Similar to traditional square opening mesh panels, but it offers a larger open area and higher throughput, delivering precise material stratification and cleaner products.

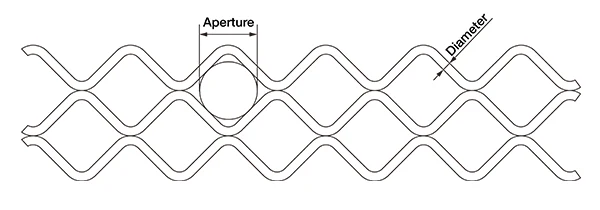

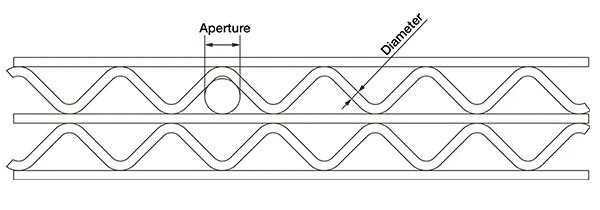

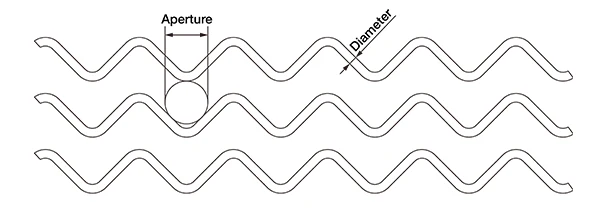

Self-cleaning screen mesh is constructed by bonding high-quality metal wires with polyurethane strips or weaving them together. During the screening process, high-frequency vibration causes each wire to oscillate at a different frequency, creating a self-cleaning effect. Additionally, the screen openings are mostly irregular in shape, significantly reducing the risk of clogging, binding, and blind areas. This design enables efficient screening of various wet, sticky, and difficult-to-process materials in mining, quarrying, aggregate processing, and the sand & gravel industry.

| Grade | High Carbon Steel Wire Chemical Composition (%) | Grade | Stainless Steel Wire Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | C | Ni | Mn | Cr | ||

| 45 | 0.42–0.50 | 0.52–0.60 | 0.50–0.80 | 304 | ≤ 0.08 | 8.0–10.5 | ≤ 2.0 | 18.0–20.0 |

| 50 | 0.47–0.55 | 321 | ≤ 0.08 | 9.0–12.0 | ≤ 2.0 | 17.0–19.0 | ||

| 55 | 0.52–0.60 | 316L | ≤ 0.03 | 10.0–14.0 | ≤ 2.0 | 16.0–18.0 | ||

| 60 | 0.57–0.65 | 2205 | ≤ 0.03 | 4.5–6.5 | ≤ 2.0 | 21.0–23.0 | ||

| 65 | 0.62–0.70 | 2207 | ≤ 0.03 | 6–8 | ≤ 1.2 | 24.0–26.0 | ||

| 70 | 0.67–0.75 | 310S | ≤ 0.08 | 19.0–22.0 | ≤ 2.0 | 24.0–26.0 | ||

| 65Mn | 0.62–0.70 | 0.90–1.20 | – | – | – | – | – | |

| 72A | 0.70–0.75 | 0.15–0.75 | 0.30–0.60 | – | – | – | – | – |

| Aperture (mm) | Wire Diameter (mm) | Open Area (%) | Aperture (mm) | Wire Diameter (mm) | Open Area (%) |

|---|---|---|---|---|---|

| 1.50 | 1.20–1.60 | 31–38 | 13.50 | 2.80 | 68 |

| 1.75 | 1.20–1.25 | 40 | 14.00 | 2.00–4.00 | 61–76 |

| 2.00 | 1.20–1.60 | 37–43 | 14.50 | 2.50–4.00 | 62–73 |

| 2.50 | 1.20–2.00 | 35–48 | 15.00 | 2.50–4.00 | 63–74 |

| 3.00 | 1.20–2.00 | 40–52 | 15.50 | 3.00–3.15 | 69–70 |

| 3.50 | 1.20–2.00 | 42–56 | 16.00 | 3.00–4.00 | 64–71 |

| 4.00 | 1.20–2.00 | 45–58 | 17.00 | 2.00–4.00 | 66–76 |

| 4.50 | 1.20–2.50 | 40–62 | 18.00 | 3.00–4.00 | 67–73 |

| 5.00 | 1.20–2.80 | 41–65 | 19.00 | 2.80–4.00 | 68–76 |

| 5.50 | 1.20–2.50 | 48–61 | 20.00 | 2.50–4.00 | 69–79 |

| 6.00 | 1.50–2.80 | 48–64 | 21.00 | 4.00 | 71 |

| 6.50 | 1.50–3.15 | 47–66 | 22.00 | 2.50–4.00 | 72–80 |

| 7.00 | 2.00–3.15 | 49–61 | 23.00 | 4.00 | 73 |

| 7.50 | 2.00–3.15 | 52–62 | 24.00 | 4.00 | 74 |

| 8.00 | 2.00–3.15 | 53–63 | 25.00 | 4.00–5.00 | 70–74 |

| 8.50 | 2.50 | 61 | 26.00 | 4.00–5.00 | 71–75 |

| 9.00 | 2.00–3.15 | 56–67 | 27.00 | 4.00 | 76 |

| 9.50 | 2.50–3.15 | 57–63 | 28.00 | 3.00–4.00 | 77–82 |

| 10.00 | 2.00–3.15 | 59–69 | 29.00 | 4.00 | 77 |

| 10.50 | 2.50–3.15 | 60–66 | 30.00 | 3.00–4.00 | 78–83 |

| 11.00 | 2.00–3.15 | 61–72 | 32.00 | 4.00 | 79 |

| 11.50 | 2.50–2.80 | 64–66 | 35.00 | 4.00–5.00 | 77–81 |

| 12.00 | 2.00–4.00 | 57–73 | 40.00 | 4.00–5.00 | 79–83 |

| 12.50 | 2.50–4.00 | 58–69 | 44.00 | 4.00 | 84 |

| 13.00 | 2.00–4.00 | 59–75 | – | – | – |

| Aperture (mm) | Wire Diameter (mm) | Open Area (%) | Aperture (mm) | Wire Diameter (mm) | Open Area (%) |

|---|---|---|---|---|---|

| 1.50 | 1.20–1.25 | 29–37 | 11.00 | 2.80–3.15 | 64 |

| 1.75 | 1.20–1.25 | 40 | 11.50 | 2.50–3.15 | 66 |

| 2.00 | 1.20–1.60 | 36–43 | 12.00 | 2.50–4.00 | 60–72 |

| 2.50 | 1.20–2.00 | 37–49 | 12.50 | 2.50–4.00 | 62–68 |

| 3.00 | 1.20–2.00 | 38–54 | 13.00 | 2.00–3.15 | 65–73 |

| 3.50 | 1.20–1.60 | 47–56 | 14.00 | 2.80–4.00 | 65–70 |

| 4.00 | 1.20–2.50 | 42–60 | 15.00 | 2.80–4.00 | 67–73 |

| 4.50 | 1.50–2.50 | 46–58 | 16.00 | 3.00–4.00 | 65–70 |

| 5.00 | 1.50–2.80 | 45–59 | 17.00 | 3.00–4.00 | 69 |

| 5.50 | 1.50–2.50 | 52–65 | 18.00 | 3.00–3.15 | 68–71 |

| 6.00 | 1.50–3.15 | 45–66 | 19.00 | 3.00–4.00 | 72 |

| 6.30 | 2.50–2.80 | 51–52 | 20.00 | 3.00–4.00 | 70–79 |

| 6.50 | 2.00–2.50 | 56–59 | 21.00 | 3.00–4.00 | 74 |

| 7.00 | 2.00–3.15 | 47–64 | 22.00 | 3.00–4.00 | 70–74 |

| 7.50 | 2.00–2.50 | 60 | 23.00 | 3.00–4.00 | 75 |

| 8.00 | 2.00–4.00 | 50–65 | 24.00 | 3.00–4.00 | 71–74 |

| 8.50 | 2.00–2.50 | 64 | 25.00 | 3.00–4.00 | 73–75 |

| 9.00 | 2.00–3.15 | 58–65 | 26.00 | 4.00 | 74 |

| 9.50 | 2.50–2.80 | 62 | 30.00 | 4.00–5.00 | 74–78 |

| 10.00 | 2.00–3.15 | 60–66 | – | – | – |

| Aperture (mm) | Wire Diameter (mm) | Open Area (%) | Aperture (mm) | Wire Diameter (mm) | Open Area (%) |

|---|---|---|---|---|---|

| 1.50 | 1.20–1.25 | 50 | 12.50 | 2.50–4.00 | 71–80 |

| 1.75 | 1.20–1.25 | 55 | 13.00 | 2.00–3.00 | 71–74 |

| 2.00 | 1.20–1.60 | 51–57 | 14.00 | 2.50–4.00 | 73–82 |

| 2.50 | 1.20–2.00 | 53–60 | 15.00 | 2.50–4.00 | 74–80 |

| 3.00 | 1.20–2.00 | 57–64 | 15.50 | 3.00 | 80 |

| 3.50 | 1.20–2.00 | 57–67 | 16.00 | 3.00–4.00 | 75 |

| 4.00 | 1.20–2.00 | 62–70 | 17.00 | 3.00–4.00 | 75–80 |

| 4.50 | 1.20–2.00 | 64–75 | 18.00 | 3.00–4.00 | 78–80 |

| 5.00 | 1.50–2.80 | 56–71 | 19.00 | 3.00–4.00 | 78–82 |

| 5.50 | 2.00–2.50 | 61–67 | 20.00 | 3.00–4.00 | 79–86 |

| 6.00 | 1.50–2.80 | 60–73 | 22.00 | 3.00–4.00 | 80–84 |

| 6.50 | 2.00–2.50 | 64–70 | 24.00 | 4.00 | 81 |

| 7.00 | 2.00–3.15 | 67–72 | 25.00 | 3.00–4.00 | 81–85 |

| 7.50 | 2.00–3.00 | 62–63 | 27.00 | 4.00 | 83 |

| 8.00 | 2.00–3.15 | 69–74 | 28.00 | 4.00 | 83 |

| 8.50 | 2.00–2.50 | 73–77 | 30.00 | 3.00–4.00 | 85–87 |

| 9.00 | 2.00–3.15 | 69–79 | 35.00 | 4.00–5.00 | 83–86 |

| 10.00 | 2.00–3.15 | 73–80 | 40.00 | 4.00 | 89 |

| 11.00 | 2.80–3.15 | 75–85 | 45.00 | 4.00 | 90 |

| 12.00 | 2.50–4.00 | 71–84 |

| Aperture (mm) | Wire Diameter (mm) | Open Area (%) | Aperture (mm) | Wire Diameter (mm) | Open Area (%) |

|---|---|---|---|---|---|

| 4 | 2 | – | 12 | 2 | – |

| 5 | 2 | – | 12 | 5 | – |

| 5 | 2.34 | – | 12.7 | 3.05 | – |

| 5 | 2.5 | – | 12.7 | 3.43 | – |

| 5 | 3.15 | – | 12.7 | 3.76 | – |

| 6 | 4 | – | 15.88 | 4.11 | – |

| 6.35 | 2.67 | – | 16 | 6 | – |

| 8 | 2 | – | 22.4 | 8 | – |

| 9.53 | 3.05 | – | 25 | 8 | – |

| 10 | 2 | – | – | – | – |

Similar to traditional square opening mesh panels, but it offers a larger open area and higher throughput, delivering precise material stratification and cleaner products.

A unique combination of crimped and straight lines creates a triangular opening shape, which absorbs impact forces and enhances dimensional accuracy.

Ideal for severe blinding applications, its large open area ensures effective size control, making it especially suitable for removing fines and similar materials.

With maximum open area, it efficiently removes sand, gravel, topsoil, fines, etc.

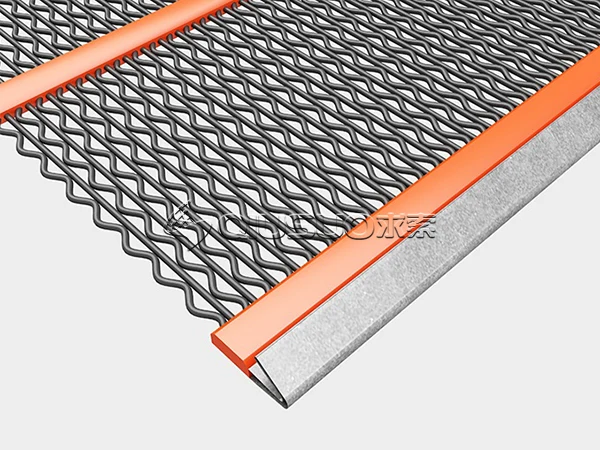

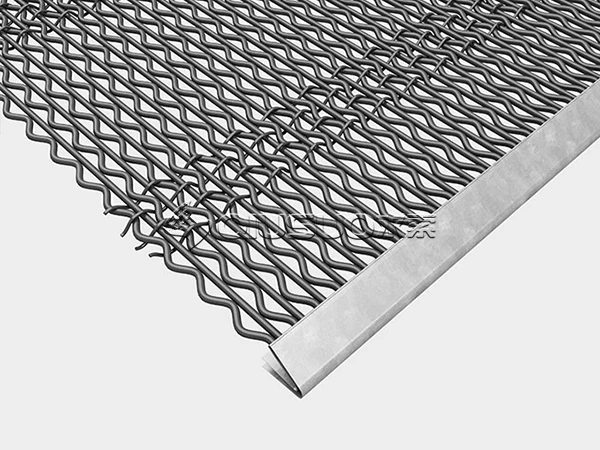

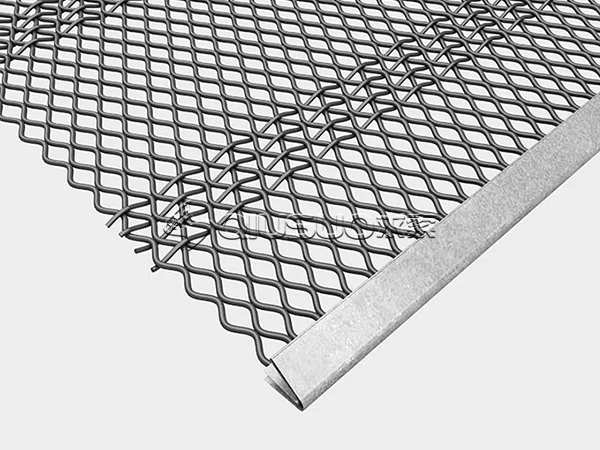

To accommodate various working conditions and screening requirements, we have developed various banding structures for self-cleaning screen mesh. The real-world images below provide a clear demonstration of the connection methods for each banding type.

Self-cleaning screen mesh efficiently screens a wide range of wet, sticky, and hard-to-screen materials in mining, quarrying, aggregate processing, and sand and gravel industries.