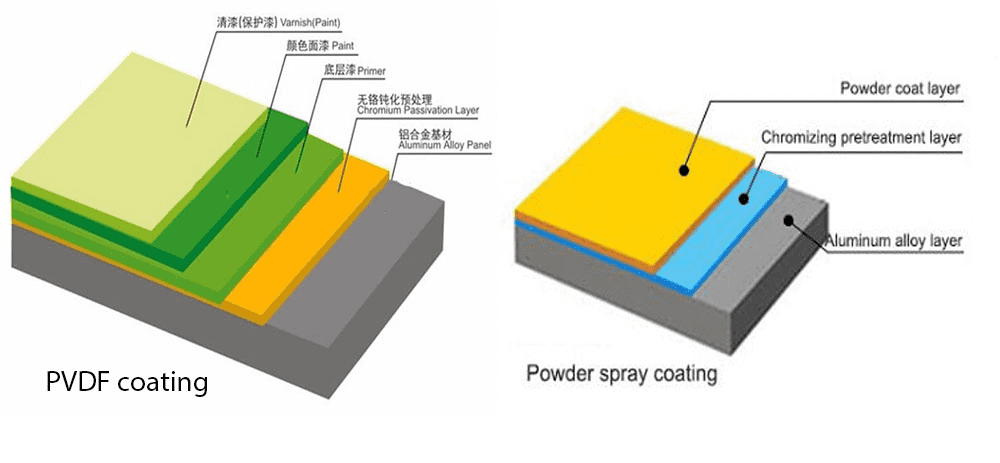

PVDF coating (polyvinylidene fluoride) a resin based liquid coating charged powder is sprayed on the metal surface.

There are customers donot know what the difference between PVDF coating and powder coating, and do not know they shall choose PVDF coating or powder coating. Here we are pleased to make a quick and simple introduction for what is PVDF coating, what is powder coating, the difference and advantage of PVDF coating and powder coating.

PVDF coating (polyvinylidene fluoride) a resin based liquid coating charged powder is sprayed on the metal surface.

PVDF coating (polyvinylidene fluoride) a resin based liquid coating system and a pure thermoplastic fluoropolymer that is non-reactive and possesses multiple coating benefits. PVDF coatings are especially resistant to solvents, acids and have a very low density compared to similar fluoropolymers.

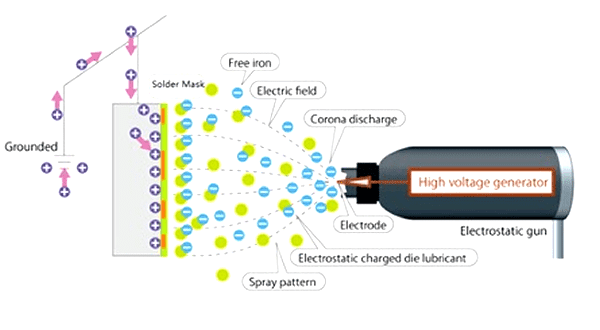

Powder Coating is an electrostatic process in which the electrostatically charged powder is sprayed on the metal surface.

Powder coating is Electrostatic spraying refers to a coating method that uses corona discharge principle to make atomized coating negatively charged under the action of high voltage direct current field and adsorbed on the surface of positively charged substrate.

Different raw material

PVDF coating raw material is Polyvinylidene fluoride

Powder coating raw material is various such as Epoxy resin, Epoxy-polyester mixture, Polyester resin, Polyurethane resin, Polyvinyl chloride (PVC), polyethylene.

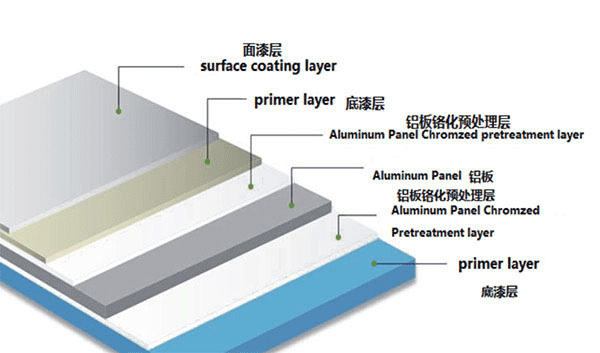

Different process

Fluorocarbon spraying process is divided into

Powder Coating Process Involves Three Basic Steps

Part preparation or the pre-treatment, the powder application, and curing.

The performance comparison

| Performance | PVDF coating | Powder coating |

|---|---|---|

| Film thickness | 35-60μm | 60-120μm |

| Wear resistance | Excellence | Good |

| Weather resistance | Over 15 years, the color is basically unchanged | 7-8 years, general 2-5 years can produce obvious chromatic aberration |

| Corrosion resistance/stain resistance | Fluoropolymers are corrosion resistant and have a smooth surface | Rough surface, easy to stain, outdoor weather resistance is general |

| Appearance | Plain color, metal color, wrinkle, sand and other artistic coatings. Can do light, matte, matt and so on. | Plain color, limited metal color. Can do light, matte, matt and so on. |

| Color uniformity | Good color consistency | Small color difference |

| Cleanliness and maintenance | Dirt is not easy to adhere to, easy to clean and maintain | Need regular maintenance |

| the price | Expensive | Economical |