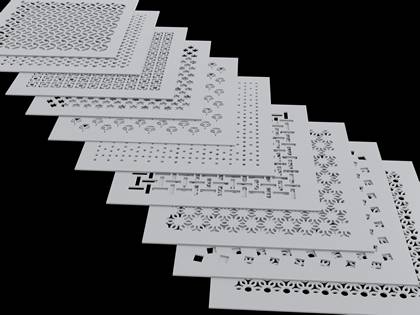

Perforated Metal Sheet

The sugar industry is the industrial process of converting raw materials (such as sugarcane or sugar beet) into sugar. This industry involves multiple stages, including the collection, washing, juicing, concentration, crystallization, and refining of raw materials. First, after washing and cutting, sugarcane or sugar beet is juiced to extract the sugar-containing liquid. Next, the sugar solution is concentrated and heated, allowing the sugar to gradually crystallize. The crystallized sugar needs to undergo centrifugation and refining to remove impurities and pigments, ultimately resulting in high-purity granulated sugar or other sugar products.

In the sugar industry, common issues during production include impurity control in the sugar solution, low crystallization efficiency, and equipment wear. Impurities in the sugar solution not only affect the purity of the final product but may also lead to instability in the crystallization process, thereby reducing yield and quality.

By optimizing sugar production processes and technologies, enhancing the efficiency of raw material processing, and developing the reuse of by-products, we can better improve the yield and quality of sugar, promote the sustainable development of the industry, meet market demands for healthy products, and create a more competitive sugar production environment for the future.