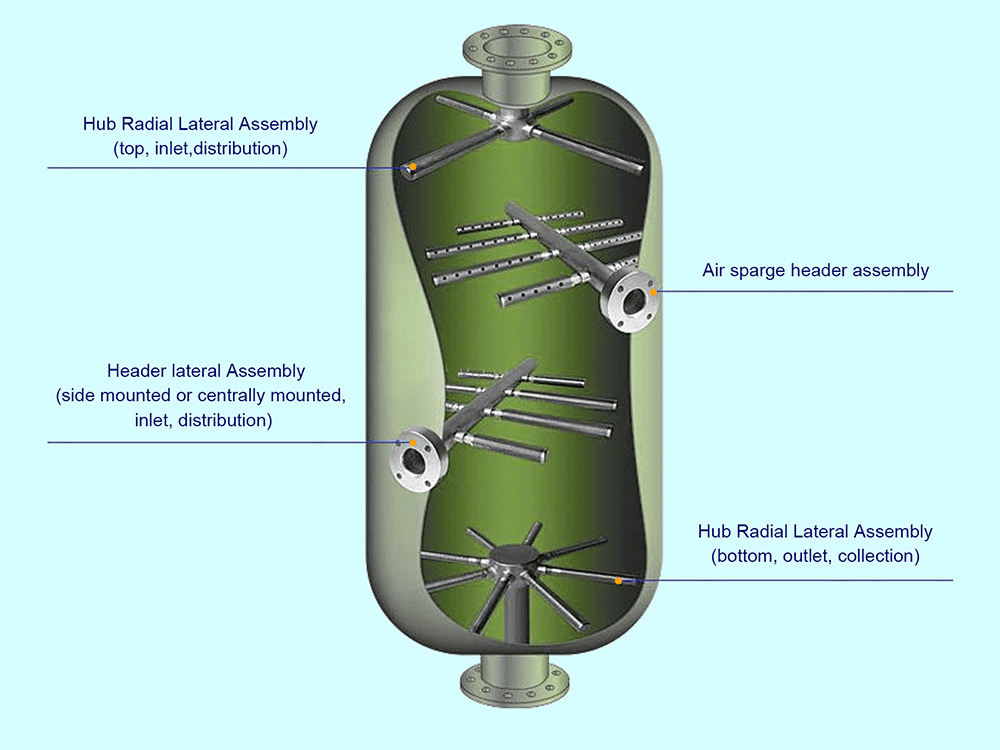

Hub Radial Lateral Assembly-Effective Distribution and Collection

Hub Radial Lateral Assembly is mounted on the top or bottom vessels, is an economical possibility for smaller vertical vessel. Our every Hub Radial Lateral Assembly can be specifically designed for your application and serves both as a collector of down-flow service and a distributor of incoming backwash water. And, for counter-current flow, flow with an inlet at the bottom of the vessel, the arrangement is inversed with the distributor at the bottom of the vessel and the collector at the top of the vessel.

The wedge wire screen can be perforated pipe based for high pressure vessels, or designed to evenly distribute flow over the entire screen area.

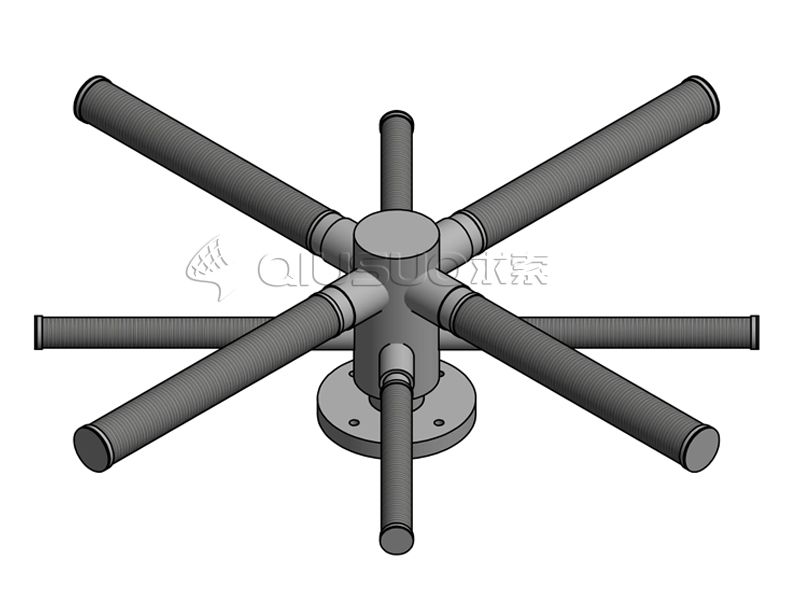

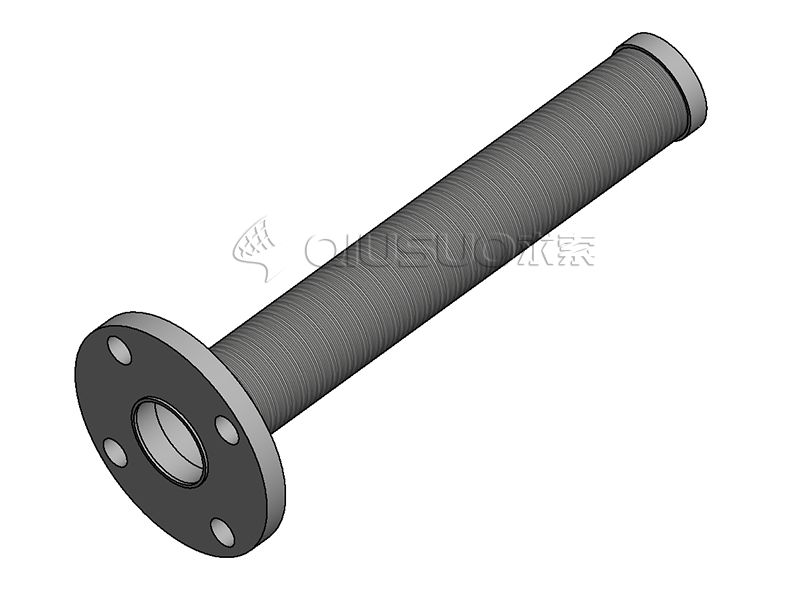

- Flange Hub

- 8 Numbers and two row lateral assemblies

- thread joint lateral assemblies

- Lateral assemblies perpendicular to hub

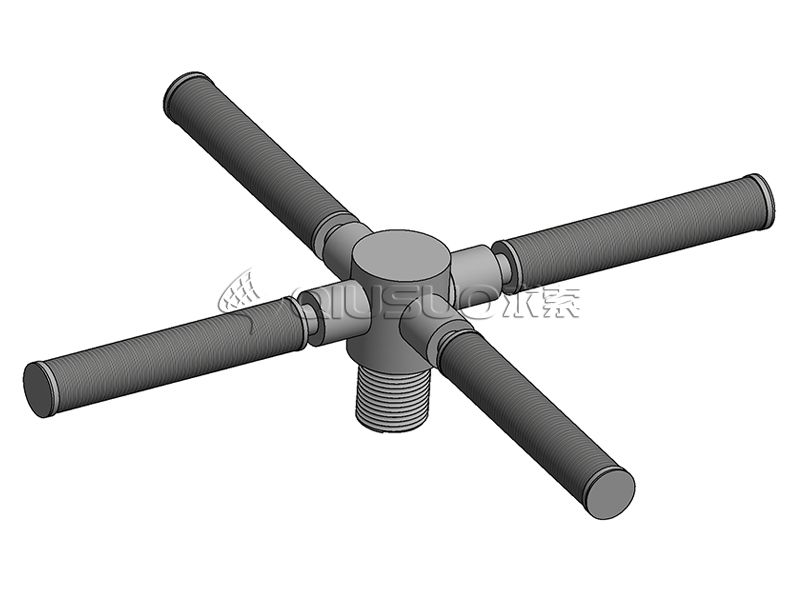

- Thread Hub

- 4 Numbers and one row lateral assemblies

- thread joint lateral assemblies

- lateral assemblies perpendicular to hub

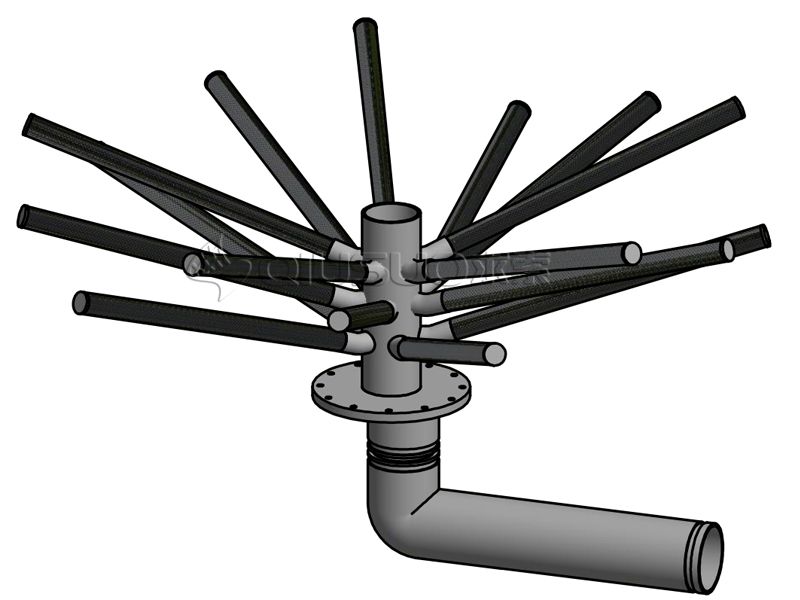

- Flange Hub

- 15Numbers and three row lateral assemblies

- Thread joint lateral assemblies

- Lateral assemblies angled to hub

Table 1: Hub Radial Lateral Assembly Specifications

| No. |

Tank Diameter |

Hub Pipe and Flange |

Laterals Screen Diameter |

Laterals Screen Length |

Numbers of Laterals |

| 1 |

40" / 1016 mm |

3" / DN80 |

25 mm, 32 mm, 38 mm, 45 mm |

300 mm – 400 mm |

4–8 |

| 2 |

48" / 1219 mm |

3" / DN80 |

32 mm, 38 mm, 45 mm, 57 mm |

400 mm – 500 mm |

4–12 |

| 3 |

54" / 1350 mm |

4" / DN100 |

38 mm, 45 mm, 57 mm, 76 mm |

400 mm – 550 mm |

8–12 |

| 4 |

60" / 1524 mm |

4" / DN100 |

38 mm, 45 mm, 57 mm, 76 mm |

550 mm – 600 mm |

8–16 |

| 5 |

72" / 1828 mm |

5" / DN125 |

38 mm, 45 mm, 57 mm, 76 mm |

600 mm – 800 mm |

8–16 |

| 6 |

80" / 2032 mm |

6" / DN150 |

45 mm, 57 mm, 76 mm, 89 mm |

700 mm – 900 mm |

8–16 |

| 7 |

120" / 3048 mm |

8" / DN200 |

57 mm, 76 mm, 89 mm, 108 mm |

900 mm – 1200 mm |

16–20 |

| 8 |

150" / 3810 mm |

10" / DN300 |

57 mm, 76 mm, 89 mm, 108 mm |

1200 mm – 1600 mm |

16–20 |

Notes:

- Special specifications are processed and produced according to the user's requirements.

- We offer perforated pipes interiors the wedge wire screen tube that can withstand high pressure.

- Material grade 304, 304L, 321, 316L, 310S, 904L, C276, S32205, S32750, Titanium Gr.2

|

Header Lateral Assembly- Designs For Horizontal Vessels

Header lateral assembly consist of a series of wedge wire screen laterals attached to a central header, it allows process engineers to design for uniform flow through the treatment media at a wider range of rates and for a variety of vessel sizes and shapes. Header lateral design for horizontal vessels is also used for square or rectangular underdrains.

Header lateral assembly can be either side mounted or centrally mounted, it provides most effective uniform distribution or collection for vertical vessels. Header lateral assembly system can be designed to accommodate a variety of process conditions and requirements, while maintaining their characteristics of high distribution efficiency.

Wedge wire screen laterals spacing, numbers, length, diameter and slot opening size are based on individual system needs. Slot sizes can be any width from 0.002 inches and up in 0.001 inch increments.

Flange joint wedge wire screen header lateral assemblies

Thread joint wedge wire screen header lateral assemblies

Table 2: Header Lateral Assembly Specifications

| No. |

Tank Diameter |

Hub Pipe and Flange |

Laterals Screen Diameter |

Laterals Screen Length

(Range from side to middle) |

Numbers of Laterals |

| 1 |

48" / 1219 mm |

3" / DN80 |

32 mm, 38 mm, 45 mm |

250 mm – 500 mm |

1–12 |

| 2 |

54" / 1350 mm |

4" / DN100 |

38 mm, 45 mm, 57 mm |

280 mm – 550 mm |

10–16 |

| 3 |

60" / 1524 mm |

4" / DN100 |

45 mm, 57 mm, 76 mm |

330 mm – 650 mm |

12–16 |

| 4 |

72" / 1828 mm |

5" / DN125 |

45 mm, 57 mm, 76 mm |

400 mm – 800 mm |

12–16 |

| 5 |

80" / 2032 mm |

6" / DN150 |

57 mm, 76 mm, 89 mm |

450 mm – 900 mm |

12–16 |

| 6 |

120" / 3048 mm |

8" / DN200 |

57 mm, 76 mm, 89 mm |

700 mm – 1400 mm |

16–24 |

| 7 |

126" / 3200 mm |

8" / DN200 |

57 mm, 89 mm, 108 mm |

700 mm – 1450 mm |

20–24 |

| 8 |

150" / 3810 mm |

8" / DN200 |

57 mm, 89 mm, 108 mm |

700 mm – 1850 mm |

20–26 |

Notes:

Special specifications are processed and produced according to the user's requirements.

We offer perforated pipes interiors the wedge wire screen tube that can withstand high pressure.

Material grade 304, 304L, 321, 316L, 310S, 904L, C276, S32205, S32750, Titanium Gr.2 |

Wedge Wire Screen Laterals-Top Customized &Designs For Different Requirements

Except of header lateral assembly, hub radial lateral assembly, if customers only need the wedge wire screen laterals, types of customized wedge wire screen laterals and resin trap also available from us.

Our wedge wire screen laterals can be as small as 0.75inches in diameter or larger.

Wedge wire screen Laterals attach to headers of hubs with either threaded fittings, couplings or flanges. A perforated pipe-base can be used inside the screen laterals for increased collapse resistance and enhanced flow distribution.

Thread joint lateral assembly

Flange joint lateral assembly

Perforated pipe based lateral assembly

Table 3: Common Used Wedge Wire Screen Laterals Specifications

| No. |

Screen Diameter |

Screen Slots |

Reinforced Perforated Pipe |

Joint type |

Related Standards |

| 1 |

30 mm |

0.2 / 0.3 / 0.5 / 1 mm |

1/2" Sch40, DN15 × 2.5 |

thread pipe joints 1/2", G15 |

ANSI/ASME B1.20.1.

ASME B16. 5

GB/T 29168 |

| 2 |

38 mm |

0.2 / 0.3 / 0.5 / 1 mm |

3/4" Sch40, DN20 × 3 |

thread pipe joints 3/4", G20, |

| 3 |

45 mm |

0.2 / 0.3 / 0.5 / 1 mm |

1" Sch40, DN25 × 3.5 |

thread pipe joints 3/4", 1", G20, G25 |

| 4 |

50 mm |

0.2 / 0.3 / 0.5 / 1 mm |

1-1/4" Sch40, DN32 × 3.5 |

thread pipe joints 3/4", 1", G20, G25 |

| 5 |

57 mm |

0.2 / 0.3 / 0.5 / 1 mm |

1-1/2" Sch40, DN40 × 4 |

thread pipe joints 1", 1-1/4", 1-1/2", G25, G32, G40 |

| 6 |

76 mm |

0.2 / 0.3 / 0.5 / 1 mm |

2" Sch40, DN50 × 4 |

Flange 2", DN50 |

| 7 |

105 mm |

0.2 / 0.3 / 0.5 / 1 mm |

3" Sch40, DN80 × 5.5 |

Flange 3", DN80 |

| 8 |

130 mm |

0.2 / 0.3 / 0.5 / 1 mm |

4" Sch40, DN100 × 6 |

Flange 4", DN100 |

Notes:

Wedge Wire Screen Laterals for water inlet device comes in various forms cross type, multi-branch type, straight pipe type, etc.

Special specifications are processed and produced according to the user's requirements.

We offer perforated pipes interiors the wedge wire screen tube that can withstand high pressure.

Material grade 304, 304L, 321, 316L, 310S, 904L, C276, S32205, S32750, Titanium Gr.2 |

Technical Information-Reference for Your Designs or Purchasing

There are technical drawings and technical information for you designs or purchasing the header and hub lateral assembly.

| Material grade: |

304, 316, 316L,321,410S, 904L,TA2, HASTELLOY C-276

DUPLEX 2205, SUPER DUPLEX 2507, other metal alloy materials |

| Screen Lateral size: |

Lateral spacing, length, diameter and slot opening size are based on individual system requirements |

| Whether Perforated pipe based: |

Perforated pipe liners can be used inside screen laterals for increased collapse resistance and enhanced flow distribution |

| laterals assemblies joint type: |

standard thread

fabricated flanges

fully welding types |

| Header or Hub connection size: |

QIUSUO's Wedge Wire Screen laterals and pipe-based Wedge Wire Screen laterals available in both header-lateral and hub-lateral assemblies, the size is 1.5",2",3",4",5" and others |

| Header or Hub connection type: |

Flange (RF/SO), Flange (Blind), Flange (Socket),Flange (ANSI), Flange (Custom), Coupling, Threaded end or others |

| Header or Hub Coupling orientation: |

Angled(Please insert angle degree if known), Perpendicular to hub |

| Lateral Assembly Qty.: |

one row, two rows or three rows.

Numbers wedge wire screen Lateral |

| Max flow: |

GPM |

| Vessel size: |

Vessel size, better providing the Vessel drawings |

| Applications &usages: |

Advise us more information is helpful. |

| Surface Treatment: |

passivation, pickling, stress relieving, polishing, chrome plating |

Feature and Advantages

- Continuous & uniform slot design, high open area, non-clogging high filtering efficiency

- Economical due to Corrosion and rust resistance long life, and easy to install and replacement.

- A perforated pipe-based Lateral Assemblies High pressure resistance.

- Top customizing, laterals can attach to headers or hubs by many designs.

- Quality documentation are available, including material mill certificates, welding procedure specifications and various other reports and certifications

Inlet Hub Radial Lateral Assembly

Oulet Hub Radial Lateral Assembly

Hub Vessel Lateral Assembly for Ion Exchange Mixed Bed

Header Vessel Lateral Assembly for Ion Exchange Mixed Bed

Wedge Wire Screen Laterals

Wedge Wire Screen Laterals

Wedge Wire Screen Laterals

Wedge Wire Screen Laterals

Applications

Our tops customs stainless steel wedge wire vessel lateral assemblies and wedge wire screen laterals is ideal parts for water treatment & media Retention, and our wedge wire vessel lateral assemblies are important components for the following applications.

- Under Draining Filtration

- Lon Exchanger

- Cation Exchanger

- Mixed Bed Exchanger

- Sand Filters

- Carbon Strip Vessels

- Carbon Towers

- Clay Filters

- Other Water And Waster Water Treatment

Through client cases, you can learn our excellent product quality and process in-depth, and feel the quality of pressure screen drum.

QIUSUO is committed to delivering wedge wire vessel lateral assembly of superior quality. Our stringent quality control process ensures that you receive a reliable product that meets the highest standards.