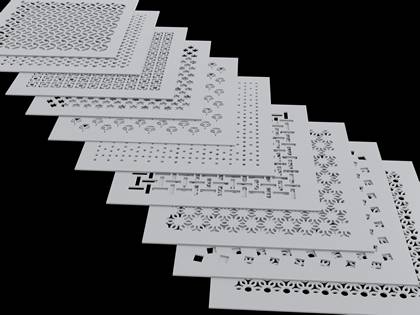

Perforated Metal Sheet

The food and beverage industry involves the production, processing, and distribution of food and beverages to ensure their safety and quality meet relevant standards. This industry encompasses various fields such as agricultural product processing, beverage manufacturing, and food service, employing multiple technological methods, such as preservation, packaging, and quality control, to ensure the safety and freshness of food. As consumer awareness of healthy eating and sustainable development increases, the food and beverage industry is continuously innovating to enhance production efficiency and environmental standards in response to the increasingly severe challenges of food safety issues and resource waste.

Unstable raw material quality can lead to a decline in product taste and safety, while cross-contamination may pose food safety risks, affecting consumer health. Moreover, low production efficiency not only increases production costs but may also delay product launch times, impacting market competitiveness. Equipment failures and improper maintenance during the processing can also lead to production line stagnation, further increasing operational risks.

By optimizing quality control and safety management in the food and beverage production process and promoting green production technologies, we can better ensure food safety, promote sustainable development, ensure product quality and nutritional value, and create a healthier living environment for consumers.