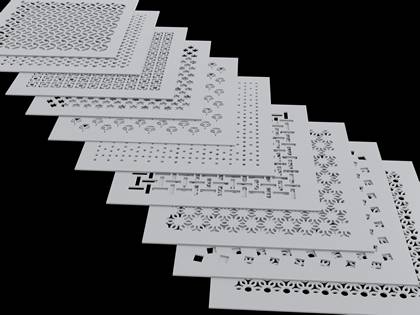

Perforated Metal Sheet

The pulp and paper industry is an important industry that transforms wood and plant fibers into paper and related products, mainly including raw material preparation, pulping, paper manufacturing, and post-processing stages. The industry processes raw materials into pulp through chemical and mechanical methods, which are then formed, pressed, and dried on a paper machine to ultimately produce various types of paper. With the increasing awareness of environmental protection, the industry is gradually adopting sustainable production methods, emphasizing resource recycling and reducing environmental impact.

Common issues encountered during the filtration and screening processes in pulp and paper production include fiber clogging, incomplete removal of impurities, and reduced screening efficiency. Fiber clogging can lead to decreased fluidity of the pulp and reduced production efficiency, while incomplete removal of impurities may affect the quality of the paper.

By optimizing the pulping and papermaking processes to enhance energy efficiency and raw material utilization, we can better reduce the environmental impact of production, promote sustainable development, ensure the quality and eco-friendliness of paper products, and create a greener production environment for the future.