DSM screen for dehydration

DSM screen is an economical and practical solid-liquid separation equipment without power equipment. Here, we discuss how DSM mesh works and how to improve processing efficiency.

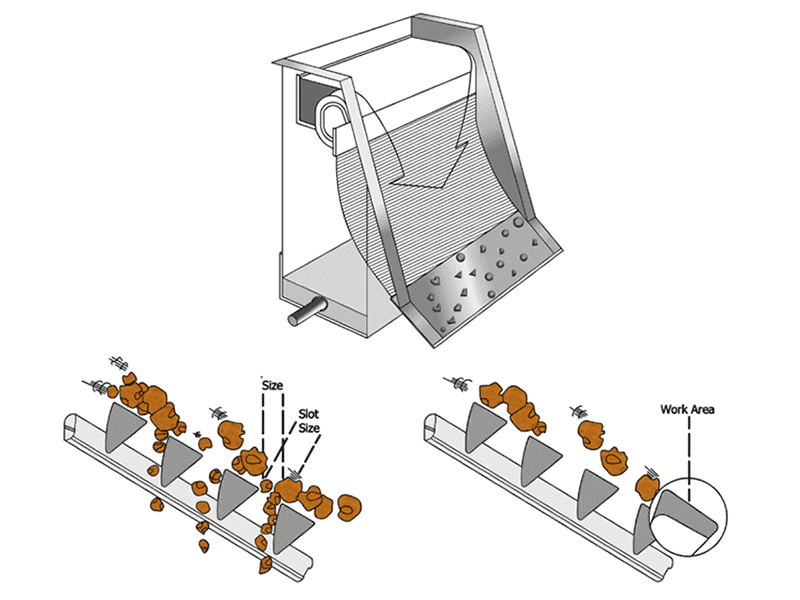

Working Principle

DSM Screen, also known as Sieve Bend Screen, is an economical and practical solid-liquid separation equipment, mainly used in coal preparation plants and mineral processing plants for pre-dehydration, desliming, media removal, and coal slime recovery.

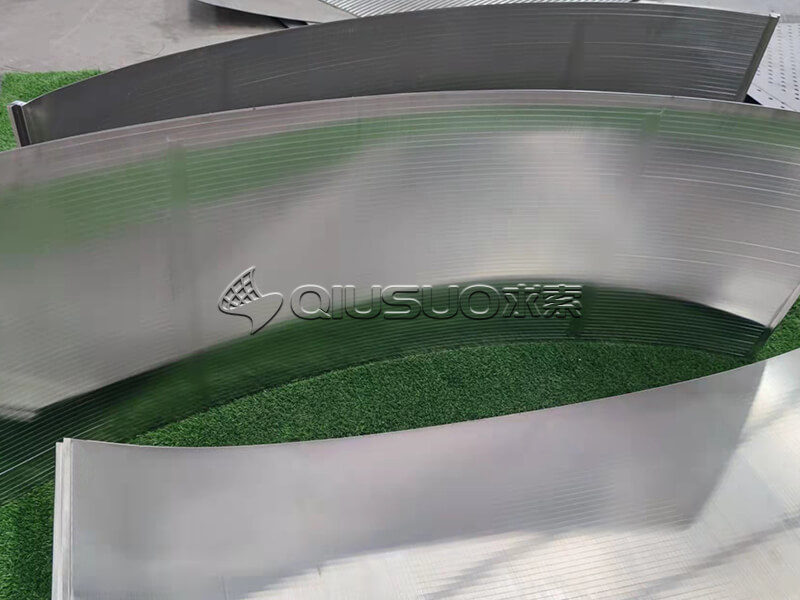

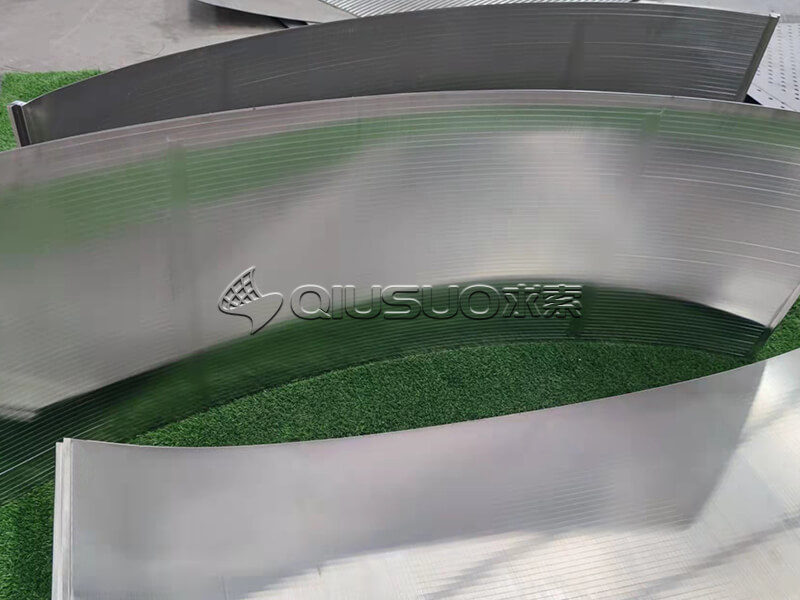

The working principle is based on a set of fixed wedge wire panels, which are arranged on a curved surface. The orientation of the panels is perpendicular to the direction of the slurry movement on the screen surface, and they are made of stainless steel or nylon. The spacing between the panels corresponds to the screen aperture size. The slurry is delivered to the screen surface at a certain speed along the tangent direction of the curved surface through the narrow slit discharge outlet at the bottom of the feeder.

As the slurry moves on the screen surface, it is subjected to gravity, centrifugal force, and the resistance of the screen bars, causing the slurry to move closely along the screen surface. The slurry near the bottom of the screen bars has a lower velocity, and during the flow, the edge of each screen bar cuts through the slurry layer. A layer of slurry about 1/4 the size of the screen apertures and the fine particles within it are cut and discharged, forming the under-screen product. The uncut slurry and coarse particles will pass over the screen surface and be discharged from the end of the screen, forming the over-screen product.

The materials are divided into different size classes by screening through the arc screen.

How to improve work efficiency?

High Efficiency Verification than Ordinary Flat Wedge Wire Screen

The slime of sedimentation tank with particle size of 0.5-1mm and fine sand with particle size of 0.15-1mm were used to compare the treatment efficiency of ordinary wedge wire screen and DSM screen. The treatment capacity of DSM screen with 2 m2 sieve surface was 190 m3 / (m2 * h). And ordinary Flat wedge wire screen to achieve the same processing capacity requires 12 planes of the total area of about 60 m2 wedge wire screen.

Someone in the Soviet Union compared the processing capacity of the DSM screen and the vibrating screen under the same conditions. Although the efficiency of the vibrating screen was 20% higher than that of the ordinary wedge wire screen, the unit area processing capacity of the same separated particles was only the DSM screen 1 / 20.

We offer three types of wedge arc screen panels: arc wedge screen panels for static and vibrating decks, DMS screen panels, and custom dewatering screen panels, with support for custom frame designs. If you require our customized products, please feel free to contact us.

DSM screen for dehydration

DSM screen for material separation

DSM screen for screening corn starch

DSM screen for sugar production