- Home

- Products

- Perforated Metal Products

- Metal grating

- Wedge Wire Screens

- Wedge Wire Slot Tubes

- Wedge Wire Strainer Elements

- Flat Wedge Wire Screen Panels

- Sieving Bending Wedge Wire Screen

- Pressure Arc Screen for Starch

- Wedge Wire Grates

- Intake Screens

- Vessel Lateral Assembly

- Resin Trap Screen

- Filter Nozzle

- Wedge Wire Screen Cylinder

- Screw Press Screen

- Rotary Drum Screen

- Pressure Screen Drum

- Metal Wire Mesh

- PU Screen

- Industry

- Fabrications

- Service

- Technology

- Safety Grating Walkway

- Safety Grating Stair Tread

- Safe Grating Ladder Rung

- Safety Grating Scaffolding Plank

- Perforated Metal Vibrating Screen for Mining Screening

- Brick Plant Vibrating Screen

- Brewery Mash Tun Floors

- Sugar Industry

- Grains Industry

- Paper Making Industry

- Pipe Schedule Chart

- Metal Wire Gauge Chart

- Metal plates gauge chart

- What are the advantages of CNC punching?

- What Are Benefits of Surface Sandblast of Drilling Screen Plate?

- Comparison of Various Intake Screens

- Why Choose Wedge Wire Screen For Brewery Mash Tun False Bottom?

- Why Twin Screw Press Machine prefer to drilling plates?

- DSM Screen Improves Processing Efficiency

- What Is the Difference for PVDF Coating and Powder Coating?

- Inspection and Test Equipment for Checking Weaving Metal Wire Cloth

- How To Calculate the Stainless Steel Welded Wire Mesh Weight?

- Construction Types Flowing Direction Wedge Wire Screen Tube

- What Are the General Types of Wire Mesh Filter Elements and Strainers?

- Inspection and Test Equipment for Checking Perforated Metal

- What Materials Grade for Woven Wire Mesh and Cloth?

- How Many Edge Types of the Stainless Steel Welding Wire Mesh Panels?

- What Is Difference Between the Opening and Mesh for Welding Wire Mesh?

- What Holes Pattern Perforated Metal Anti-Slips Safety Gratings We Can Make?

- Wedge Wire Screen Highly Improving Sugar Manufacturing Efficiency

- Quick and Easy Reference Data and Order Tips for Stainless Steel Wire Cloth

- What’s The Difference Between Perforated Metal Tube And Perforated Metal Pipes?

- How to Choose Stainless Steel Material Grade for Your Metal Wire Mesh Products?

- How to Choose Metal Wire Mesh?

- Stainless Steel Wire Mesh/Wire Cloth Reference Data and Order Tips

- How to Calculate the Stainless Steel Wire Mesh Weight?

- Calculators

- Download

- RFQ Forms

- Technology

- Case Studies

- Industry Filtering Wire Cloth

- 100 Mesh Stainless Steel Wire Mesh

- SS310 Stainless Steel Woven Wire Cloth

- 50 mesh Stainless Steel Woven Wire Cloth

- 3 mesh Selvage Edge Woven Wire Mesh

- 325 × 2300 mesh Dutch weave wire mesh cloth filter

- 260 × 40 mesh

- 132 × 17 mesh

- Filter Wire Cloth

- 8mesh Selvage Stainless Steel Wire Mesh

- 6mesh stainless steel wire mesh

- 4mesh×0.8mm wires stainless steel wire mesh

- 3×3mesh Selvage Stainless Steel Wire Mesh

- 60mesh×0.15mm Wire Cloth Belt

- 310 40 mesh × 0.25 mm Wire Cloth

- Reverse Dutch Wire Cloth Belt

- 4×4mesh Selvage Stainless Steel Wire Cloth

- 12×64mesh Plain Dutch Weave wire mesh

- Stainless Steel Wire Mesh Filter Disc

- Wedge Wire Screen Filters

- 0.1 & 0.3 mm Slot Wedge Wire Filter Elements

- SS304 Wedge Wire Screen Cylinder

- SS304 Wedge Wire Screen Water Distributor

- SS304 Wedge Wire Intake Screen

- SS316 Wedge Wire Filter Nozzle

- 6 Inch FNPT Wedge Wire Slot Tubes

- BSPT Thread Wedge Wire Screen Filter Elements

- Duplex 2205 Wedge Wire Screen Strainer

- SS304 Flat Wedge Wire Screen Panels

- SS316 Wedge Wire Screen Panel

- T-Type Intake Screen

- Wedge Wire Screen Lower Distributor

- Wedge Wire Header Lateral Assemblies

- S32750 Wedge Wire Screen Cylinder

- SS316L Wedge Wire Screen Cylinder

- SS304 Wedge Wire Screen Cylinders

- SS304 Screw Press Separator

- Round Support Rod Wedge Wire Screen Panels

- 80 Micron Wedge Wire Screen Tube

- Drum-Type Intake Screen

- Wedge Wire Screen with Frame

- SS304 Sieve Bend Screen

- SS304 Wedge Wire Filter Screen

- Duplex 2205 Wedge Wire Screen Tube

- Hastelloy C276 wedge wire screen tube with Corrosion Resistance

- 1'' #150 BSPT Wedge Wire Screen Filter Laterals

- 3/4" NPT Threaded Nozzle with Efficient Filtration

- Wedge Wire Lateral Assemblies with High strength and rigidity

- M45x2.0 FOTI 0.2mm Slot Wedge Wire Screens

- O.D. 54 mm Wedge Wire Screen Tube

- Vibration Wedge Wire Screen Panel

- Sewage Treatment DSM Screens

- Wedge Wire Screen Panel for American down jacket company

- 120 Degrees 50 Microns DSM Screen For Starch Screening

- Thread Joint Wedge Wire Screen Water Distributor Inside Vessel

- Wedge Wire Screens With 33 MM Outer Diameter

- Flat Screen With Rectangular Support Rods

- Wedge Wire Intake Screen as Safeguard for Intake System

- 1 Inch NPT Wedge Wire Screen Nozzle

- Wedge Wire Filter Cartridge for Ballast Water Treatment Systems

- Duplex 2507 small intake screen

- 20 microns wedge wire screen filter

- Flat Plate Double Flow Rating Filter Nozzle for Filtration Tank

- Wedge wire screen basket

- Screw Press Separator Wedge Wire Screens for Agricultural Branch

- Wedge Wire Screen Grid for Beer Factory

- Wedge Wire Screen Tube for Water Pump Project

- Wedge Wire Filter Screen Segments for Chemical Plant

- Resin Trap Screen for ion Exchange & Other Media Filter Systems

- Wedge Wire Screen Laterals for Water Treatment System

- Wedge Wire Screen Filter Nozzle for Water Distribution System

- Wedge Wire Screen Tube for Welding and Machining Company

- DSM Screen for Sugar Making

- Wedge Wire Screen Nozzle For Fertilizer Plant

- 120° Static Starch DSM Screen

- Wedge Wire Drip Tray

- Wedge Wire Screen Distributors and Resin Trap

- SS304 Wedge Wire Screen Laterals

- 0.4mm Slots Wedge Wire Screen Flat Panels

- Wedge Wire Screen Scrubber

- Wedge Wire Screen Water Distributor

- Industry Perforated Metal

- SS304 & MONEL Welded Perforated Metal Tubes

- 18.8% Open Rate Perforated Metal Disc Filters

- 316L Stainless Steel Perforated Tube

- Height 86.9 mm Conical Filter Cartridge

- SS316 Fan-shaped Perforated Plates

- Laser Perforated Plate for Centrifuge Screen

- Custom Stainless Steel Filter Basket

- Q235B Mild Steel Metal Perforated Plate

- SS304 Bending Perforated Plate

- 150 mm O.D. Drilling Perforated Metal Disc

- Laser Square Perforated Plate

- Laser Drilling Micro Perforated Disc

- 0.6 mm Laser Drilling Perforated Metal Cylinder

- 0.3 mm Laser Micro-Perforation Plate

- 0.15 mm Laser Cutting Perforated Metal Ring

- 0.1 mm Laser Micro-Perforation Plate

- Round Hole Perforated Mesh Screen

- Micro Hole Perforated Metal for Twin Roll Press

- Perforated Tube Filter Element

- Drilling perforated metal cylinder with reinforced support, 2mm thickness

- Stainless steel 304 micro drilled metal filter cylinder device

- 6mm thick drilling Perforated Metal Disc

- 0.5mm Hole Diameter Perforated Plate

- 0.4 mm micro perforated mesh for coffee filtering

- Drilling Perforated Dewatering Backing Plate

- Perforated Filter Disc

- Perforated Metal Mesh Cylinder

- Drilling Perforated Metal Plate For Iran Petrochemical Industry

- SS316 0.5mm diameter micro perforated plate

- Galvanized metal grid

- Perforated tubes with different hole sizes & inside diameters

- Paper Pulp Drilling Perforated Screen Plates

- Press Screw Perforated Plate

- Drilled and Milled Perforated Plates

- Perforated Metal for Dewatering Equipment Manufacturing

- Slotted Aluminum Perforated Metal Sheet

- Customized Perforated Metal Sheet with Special Pattern

- Perforated Metal Sheet with Turbofan Hole Pattern

- Galvanized Steel Rectangular Hole Metal Sheet

- Customized Perforated Metal Sheet with Special Pattern

- Perforated Metal Pipe for Machinery and Equipment

- Galvanized Steel Sheet With Square Hole

- Perforated Galvanized Steel Sheet for Feed Machine Factory

- Micro Hole Perforated Metal Plate For Food Industry

- Micro Hole Perforated Metal Plate

- Perforated Metal for Industrial Filtering

- Micro Hole Perforated Metal Plate for Optical Coatings

- 304L 4'×8' R4T6 Perforated Sheet

- 70% Opening Hexagonal Perforated Gratings

- 6mm Holes Stainless Steel Perforated Plates

- 2mm Holes Stainless Steel Perforated Sheet

- TP321 Perforated Corrugated Plates

- SS316L Perforated Mesh Discs for Electric Motors

- Etched Micro Hole Perforated Metal Discs

- Steel Perforated Metal Tube

- Architectural Perforated Metal

- Custom SS316L Corrugated Perforated Metal Panels Decorative & Architecture

- Galvanized decorative custom hole shape perforated sheet for building Wall Cladding

- 6061 T6 Decorative Aluminum Perforated Panels

- Perforated Corrugated Sheet for construction project

- Perforated Aluminum Sheet for Exterior Wall Decoration

- Corrugated Perforated Aluminum Sheet for Exterior Wall Decoration

- Exterior Wall Aluminum Plate for Auto 4S Shop

- Corrugated Perforated Sheet Cladding

- Customized Sunshine Shield Panels

- Perforated Aluminum Gutter Covers

- Triangle Hole Perforated Sheets

- Perforated Mirror Stainless Steel Panel

- Triangle Holes Aluminum Perforated Panels

- Aluminum Perforated Sheet

- Perforated Corrugated Metal Panels

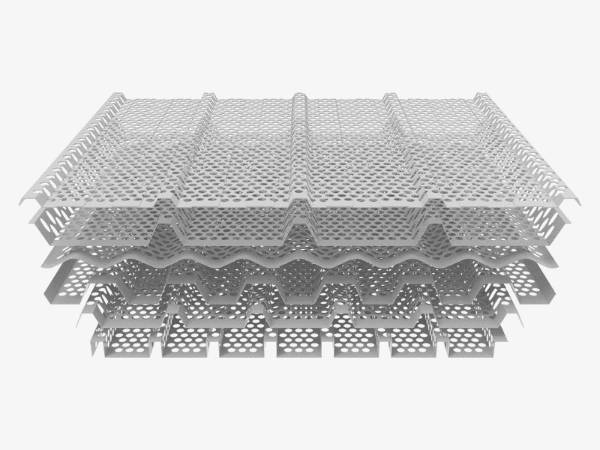

- Perforated Metal Safety Grating

- Rhombus-Lock and Round Raising Safety Grating

- A5052-H32 Grip Strut Plank Safety Grating

- SS304 Grip Strut Plank Safety Grating

- Breakout Stars Safety Grating

- SS316 Traction Tread Plank Grating is Anti-Slip and Rust Resistance

- Anti Skid Dimple Galvanized Metal Mesh

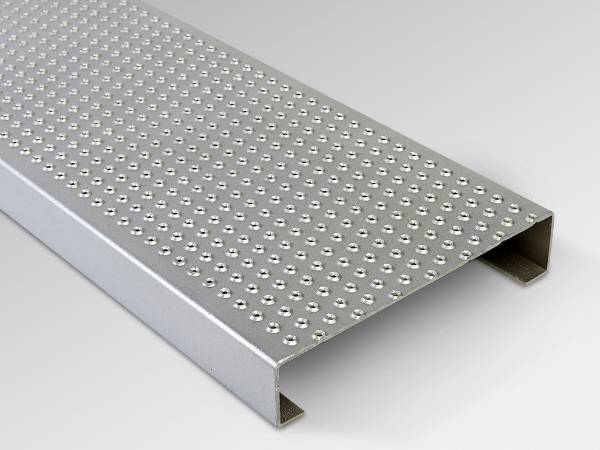

- STEP PRF-5-GRIP Traction Tread Plank Grating

- Grip Strut Plank Grating for Outdoor Industrial Production

- Anti Skid Dimple Perforated Metal Plates

- Diamond Plank Safety Grating

- Slip-Resistant Ladder Rungs

- 36" and 30" Heavy Duty Grip Strut Walkway

- Customized Breakout Stars Safety Grating

- 10" 5 holes Perf-O Grip Safety Grating

- Hot Dipped Galvanized Diamond Grip Plank

- Perf-O Grip Walkway Grating

- interlock safety grating plank

- Traction Grip Plates for Vessels Stairs

- BAR GRATING

- Stainless Steel Welding Mesh

- 3 mm Wire Diameter Stainless Steel Wire Mesh

- ASTM 304L Stainless Steel Welded Wire Mesh

- ASTM 316L Stainless Steel Welded Wire Mesh

- Titanium Welded Wire Mesh

- SUS SS316L Stainless Steel Welding Mesh

- ASTM SS316L Stainless Steel Welded Mesh

- Rectangular Opening Stainless Steel Welded Mesh

- ASTM SS316L 1/2 inch Pressure Welded Screen

- ASTM SS321 Welded Wire Mesh

- 1 Inch X 1.5 mm Stainless Steel Welded Mesh

- ASTM SS316 1/4" Welding Wire Mesh

- Expanded Metal Mesh

- Mining Screen Mesh

- 80 mm Opening Crimped Wire Mesh

- AISI 321 Crimped Wire Mesh

- 10 mm Wire Diameter Self-Cleaning Screen Mesh

- 4.5 mm Wire Diameter 65Mn Metallic Screens

- 1.5 & 1.6 mm Wire Diameter Woven Wire Slotted Mesh

- 65MN High Carbon Crimp Wire Mesh

- 65MN Crimped Wire Mesh

- 65Mn Slotted Metal Mesh

- 65Mn Square Weave Metal Screen

- 65Mn Steel Wire for Making Mineral Screen

- Fine Machined 65Mn Crimped Mesh Screen

- 65MN Crimped Wire Mesh With Plain Hooked

- 65Mn Crimped Wire Mesh for Mining

- Crimped Wire Mesh With Reinforced Shroud Banded Edge

- Wedge Wire Screen Panel for Sifting Smaller Minerals

- SS321 Crimped Wire Mesh

- Powder coating 65MN screening

- 65MN Crimped Wire Mesh for Brick Factory

- PU Screens

- Other Metal Products

- Rubber Screen Mesh

- Industry Filtering Wire Cloth

- About Us

- Contact Us