QS-V

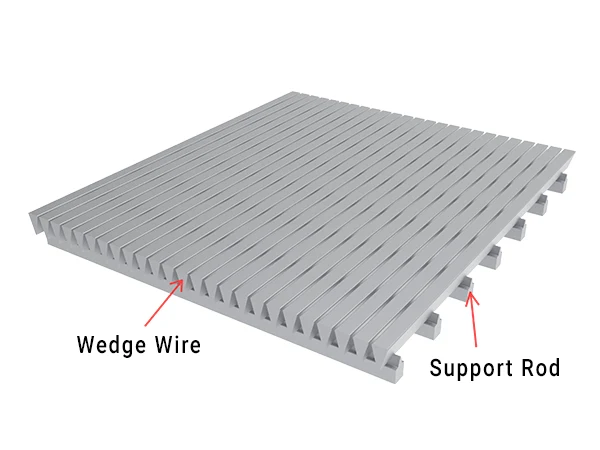

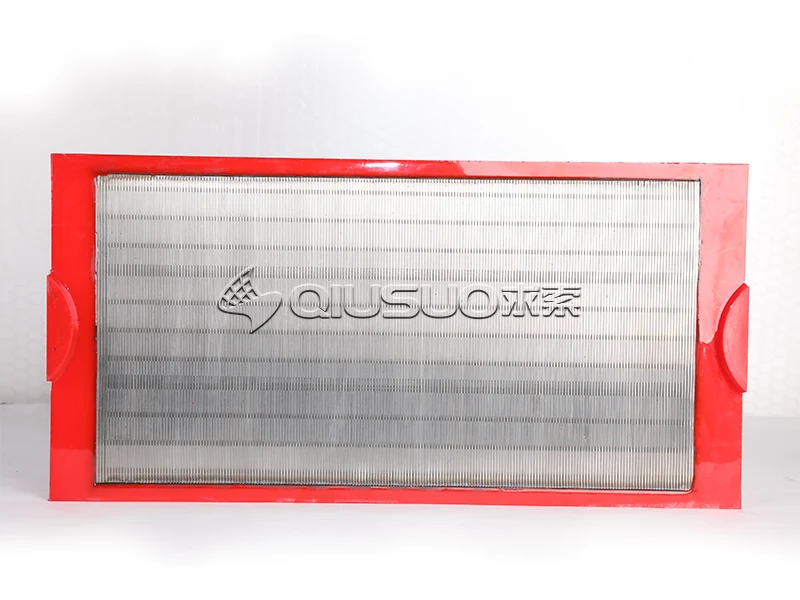

The polywedge screen panel is a composite screening medium. It consists of uniformly spaced wedge wires welded into a screening surface, externally encapsulated with a polyurethane protective layer or supported by a polyurethane frame. This design combines the high open area and drainage efficiency of polyurethane with the exceptional wear resistance of wedge wires, significantly enhancing overall abrasion resistance, corrosion resistance, and service life. It features uniform slot openings, excellent wear and corrosion resistance, and excellent dewatering and desliming performance, making it highly suitable for applications demanding both screening precision and durability in challenging operating environments.

| Specifications (mm) | 305 × 305 mm, 305 × 610 mm |

|---|---|

| Slot Size(mm) | 0.25–1 mm slot or customized |

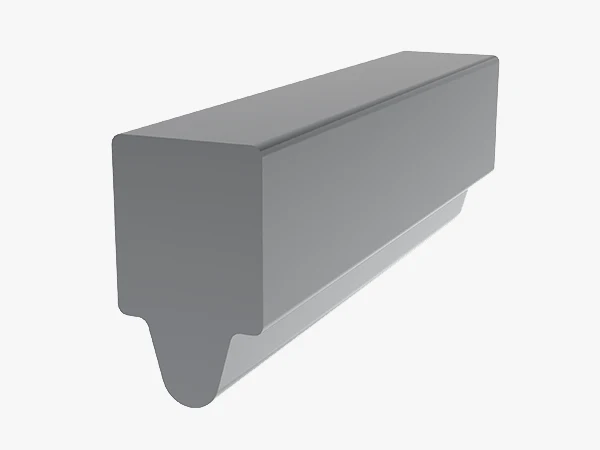

| Support Rod Type | triangle wire, round rod, flat bar or square wire. |

| Support Rod Size(mm) | 2 × 4.5 / 2 × 9.5 / customized |

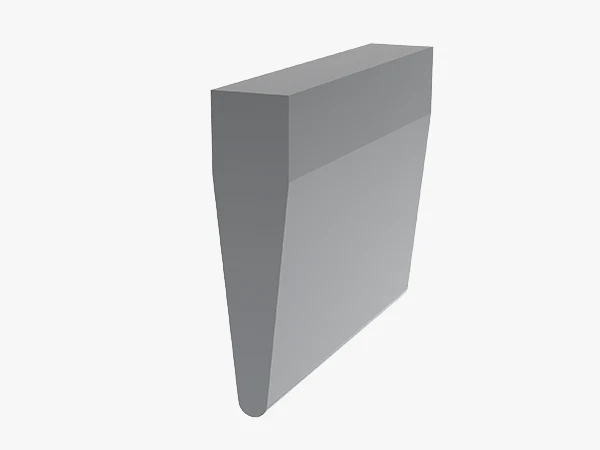

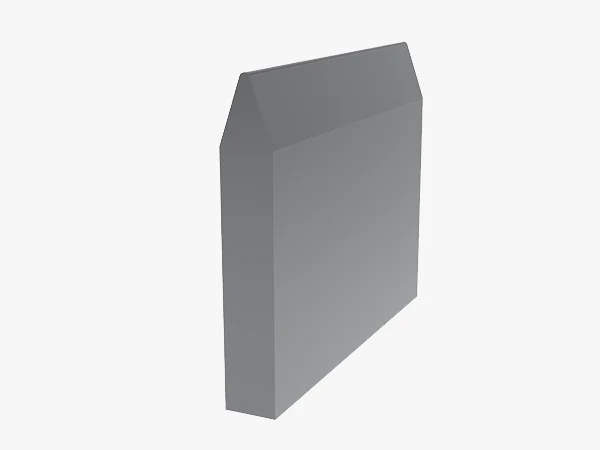

| Profile Wire(mm) | 0.5 × 1 / 0.75 × 1.3 / 1 × 2 /1.5 × 4 / 2 × 4 / 2.2 × 4.5 / 2.8 × 5 / 3 × 6 / 2.8 × 6.5 / 3.4 × 7.5 |

| Grade | Stainless Steel Wire Chemical Composition (%) | |||

|---|---|---|---|---|

| C | Ni | Mn | Cr | |

| 304 | ≤ 0.08 | 8.0–10.5 | ≤ 2.0 | 18.0–20.0 |

| 321 | ≤ 0.08 | 9.0–12.0 | ≤ 2.0 | 17.0–19.0 |

| 316L | ≤ 0.03 | 10.0–14.0 | ≤ 2.0 | 16.0–18.0 |

QS-V

QS-Q

QS-VD

QS-S-VD

QS-S-Q

QS-S-WD

QS-S-RD

QIUSUO can assist in design based on application needs and requirements, leveraging extensive experience and expertise to produce high-quality, multi-specification polywedge screen panel products with fast delivery times.

Polywedge screen panels are widely used in dewatering screens, vibrating screens, and similar equipment in coal preparation plants, coking plants, mines, power plants, dredging companies, metallurgy, petroleum, petrochemical, and related industries.