Piano wire screen with metal sliding profile

Piano wire screen, also known as harp wire screen, is a specialized screen structure composed of high-tensile steel wires tightly tensioned in parallel. Named for its resemblance to piano strings, it offers a higher open area and outstanding self-cleaning performance, effectively reducing material clogging and enhancing screening efficiency. This makes it particularly suitable for the screening of fine, wet, sticky, or easily clogged materials.

We offer customizable piano wire screens tailored to client requirements, with various wire diameters, aperture sizes, and edge connection methods, ensuring compatibility with different models of vibrating screen equipment.

| Grade | High Carbon Steel Wire Chemical Composition (%) | Grade | Stainless Steel Wire Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | C | Ni | Mn | Cr | ||

| 45 | 0.42–0.50 | 0.52–0.60 | 0.50–0.80 | 304 | ≤ 0.08 | 8.0–10.5 | ≤ 2.0 | 18.0–20.0 |

| 50 | 0.47–0.55 | 321 | ≤ 0.08 | 9.0–12.0 | ≤ 2.0 | 17.0–19.0 | ||

| 55 | 0.52–0.60 | 316L | ≤ 0.03 | 10.0–14.0 | ≤ 2.0 | 16.0–18.0 | ||

| 60 | 0.57–0.65 | 2205 | ≤ 0.03 | 4.5–6.5 | ≤ 2.0 | 21.0–23.0 | ||

| 65 | 0.62–0.70 | 2207 | ≤ 0.03 | 6–8 | ≤ 1.2 | 24.0–26.0 | ||

| 70 | 0.67–0.75 | 310S | ≤ 0.08 | 19.0–22.0 | ≤ 2.0 | 24.0–26.0 | ||

| 65Mn | 0.62–0.70 | 0.90–1.20 | – | – | – | – | – | |

| 72A | 0.70–0.75 | 0.15–0.75 | 0.30–0.60 | – | – | – | – | – |

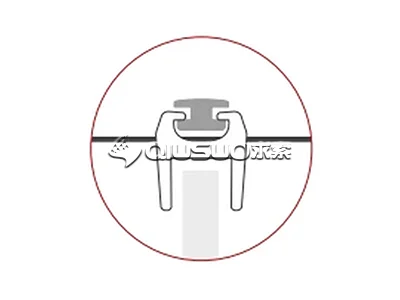

Piano wire screen with metal sliding profile

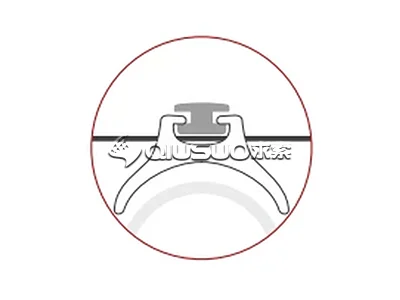

Piano wire screen with polyurethane sliding

Polyurethane non-sliding patches for fixing on the riddles of the sifters, where the supports are covered with rubber profiles.

Sliding patches for fixing on the riddles of the sifters, where the bearing bars constitute the supports.

Sliding patches for fixing on the riddles of the sifters, where the bearing bars constitute the cylinders.