Raw Material Hardness Inspection

Perforated plate screens are primarily used for high-impact applications on the upper screening surface, engineered to withstand the abrasion of screened materials. Their robust construction, combined with uniform perforations, ensures efficient separation while significantly reducing the risk of clogging or blinding. Furthermore, the smooth surface design facilitates smooth material flow, thereby minimizing the potential for material buildup or hang-up.

QIUSUO offers a wide range of perforated plate screen in various specifications and aperture sizes. To better accommodate your requirements, we provide customized solutions tailored to your exact needs.

| Grade | High Carbon Steel Wire Chemical Composition (%) | Grade | Stainless Steel Wire Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | C | Ni | Mn | Cr | ||

| 45 | 0.42–0.50 | 0.52–0.60 | 0.50–0.80 | 304 | ≤ 0.08 | 8.0–10.5 | ≤ 2.0 | 18.0–20.0 |

| 50 | 0.47–0.55 | 321 | ≤ 0.08 | 9.0–12.0 | ≤ 2.0 | 17.0–19.0 | ||

| 55 | 0.52–0.60 | 316L | ≤ 0.03 | 10.0–14.0 | ≤ 2.0 | 16.0–18.0 | ||

| 60 | 0.57–0.65 | 2205 | ≤ 0.03 | 4.5–6.5 | ≤ 2.0 | 21.0–23.0 | ||

| 65 | 0.62–0.70 | 2207 | ≤ 0.03 | 6–8 | ≤ 1.2 | 24.0–26.0 | ||

| 70 | 0.67–0.75 | 310S | ≤ 0.08 | 19.0–22.0 | ≤ 2.0 | 24.0–26.0 | ||

| 65Mn | 0.62–0.70 | 0.90–1.20 | – | – | – | – | – | |

| 72A | 0.70–0.75 | 0.15–0.75 | 0.30–0.60 | – | – | – | – | – |

QIUSUO can assist in design based on application needs and requirements, leveraging extensive experience and expertise to produce high-quality, multi-specification perforated plate screen products with fast delivery times.

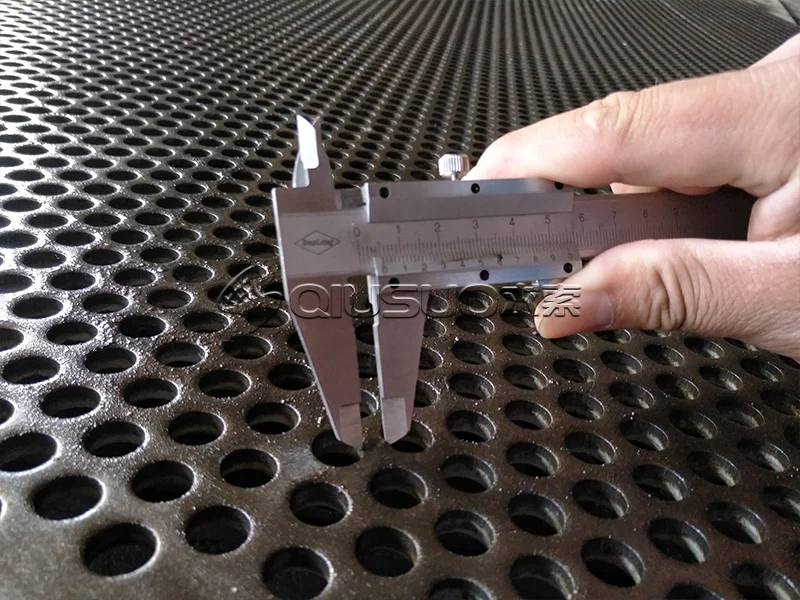

Raw Material Hardness Inspection

Perforation Production

Hole Pitch Measurement

Perforated Plate Screen s are utilized for coarse or primary screening applications, including mining, aggregate processing, road construction, and asphalt mixing plants. They are primarily employed for screening and sorting materials such as rock, ore, and gravel.

Construction waste screening

Construction waste screening

Construction waste screening