Capacity for Producing Metal Punching Sheets

We are a professional supplier of perforated metals. As a leading enterprise in the industry, we have extensive production experience, advanced processing equipment, and the capacity to produce punching perforated metal sheets while providing customers with diverse customization services. With our mastery of various advanced perforating processing techniques such as laser cutting, stamping, and punching, we can flexibly choose the best processing method according to the specific needs of our customers, ensuring product quality and performance.

High-Speed Gantry Full-Width Perforating Presses in Coils

- Fast punching. A large number of holes can be punched at one time, greatly improving production efficiency.

- Precise positioning. The precision punching system ensures the exact position of each hole.

- Ready molds. Various sizes of holes from 0.4 mm to 10 mm in diameter can be produced with ready molds.

- Width & length. Width up to 1500 mm and no length limit

20 to 500 Tons CNC Perforating Presses in Sheet

- A wide range of tonnage options. From 20 tons to 500 tons, it meets different material thicknesses and sizes.

- Large size processing capacity. Width up to 2000 mm, length up to 6000 mm, thickness up to 25 mm

- High precision punching. Advanced CNC control system ensures the position accuracy of each hole to meet the strict requirements of precision filters and other products.

- Widely applicable. Whether it is fine filter mesh, or thick super thick sieve plate, we have the most suitable perforating presses machines.

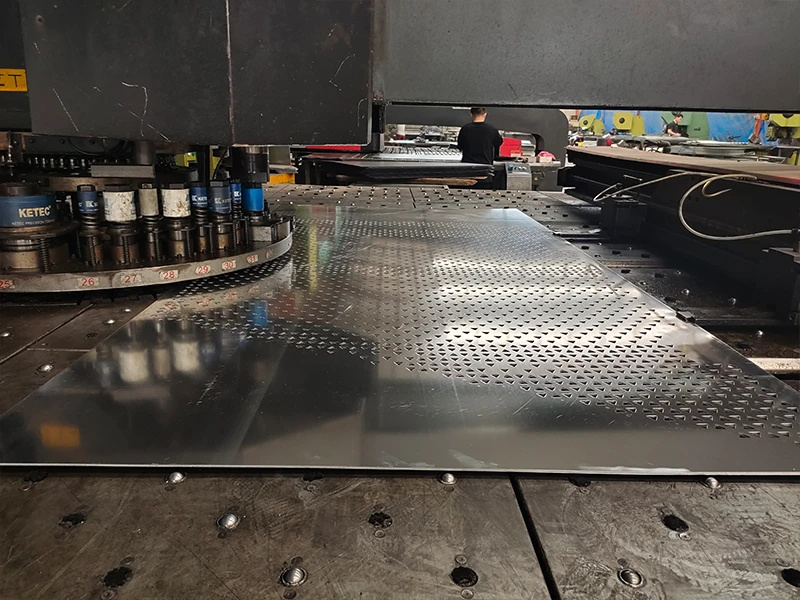

Turret Perforating Presses in Sheet

- Multi-die fast switching. The rotary multi-station design can load a variety of different punching dies at the same time. By quickly switching the mold, it can realize the processing of multiple varieties of hole patterns and hole sizes on the same production line, which greatly improves the production efficiency.

- Automatic intelligent control. The equipment is equipped with a programmable intelligent control system, which can automatically adjust various process parameters according to product requirements, such as punching strength, punching speed, etc., to achieve a high degree of automation in the production process.

Drilling Perforating for Super Perforating

- Perforation diameters much smaller than the thickness of the metal plates, with a large open area.

- Higher pressure resistance and longer service life, save maintenance and replacement costs

- Several hole sections can be selected,meet the better screening and filtration performance.

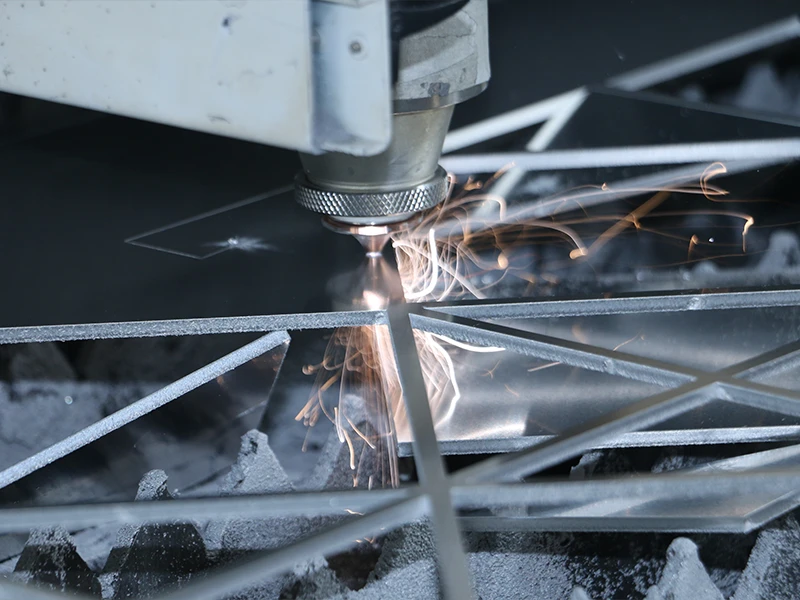

Laser Cutting for Free Perforating

- It features high cutting accuracy.

- Laser cutting is very advantageous in free holes design.