QS-V

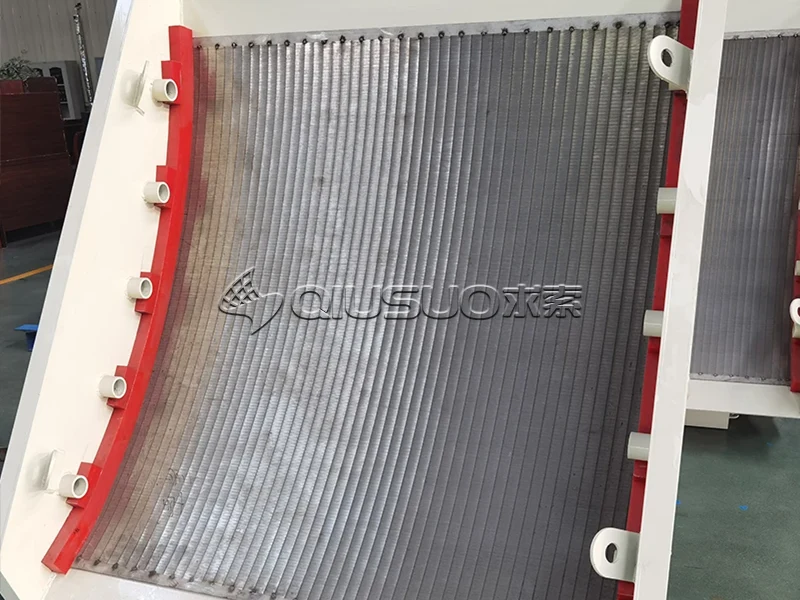

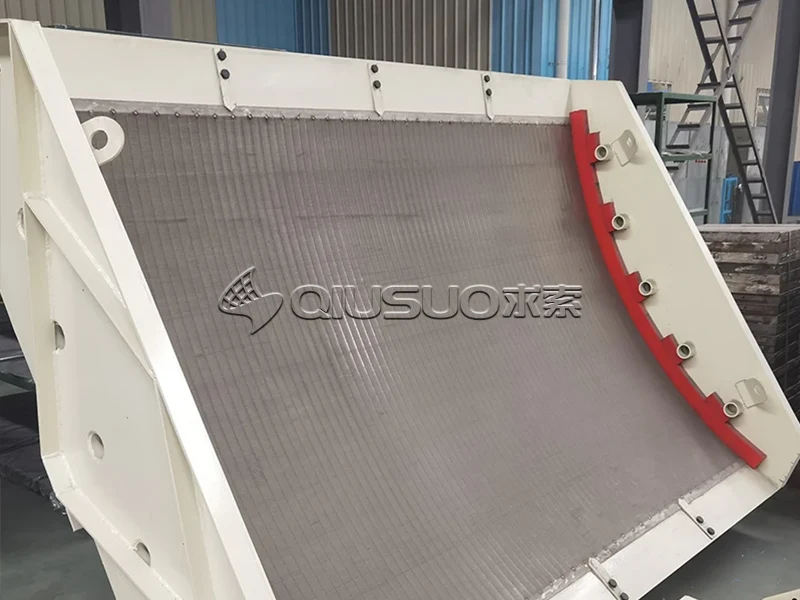

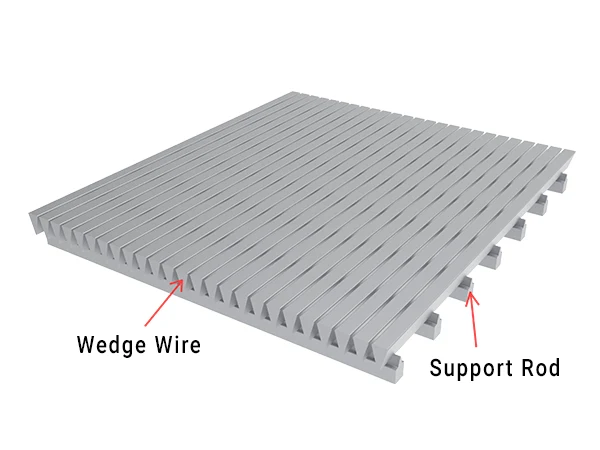

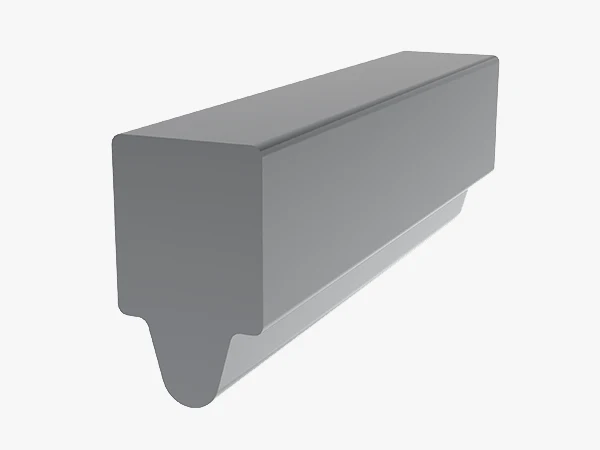

Sieve bend screen, also known as bend screen or DSM screen, is manufactured by welding stainless steel V-shaped profile wires onto wedge wire support rods. It is ideally suited for classification and dewatering operations to remove solids from liquids, or for solid/solid separation in dry feed applications. In the coal washing industry, sieve bend screens are typically used as the primary dewatering device following heavy-medium cyclones, enabling rapid and effective removal of moisture from fine materials and enhancing the efficiency of subsequent screening and classification processes.

QIUSUO provides sieve bend screens with various bending angles, arc lengths, and mesh openings to meet diverse operational requirements.

| Angles | 45° | 60° | 120° | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Radius(mm) | 1018 | 1527 | 2036 | 1018 | 1527 | 2036 | 1018 | 1527 | 2036 | |

| Arc Length(mm) | 800 | 1200 | 1600 | 1066 | 1600 | 2132 | 2132 | 3198 | 4264 | |

| Width(mm) | 600 / 900 / 1000 / 1200 / 1500 / 1800 / 2000 / 2100 / 2200 / 2400 / 2700 / 3000 / customized | |||||||||

| Slot Size(mm) | 0.25–1 mm slot or customized | |||||||||

| Support Rod Type | triangle wire, round rod, flat bar or square wire. | |||||||||

| Support Rod Size(mm) | 2 × 4.5 / 2 × 9.5 / customized | |||||||||

| Profile Wire(mm) | 0.5 × 1 / 0.75 × 1.3 / 1 × 2 /1.5 × 4 / 2 × 4 / 2.2 × 4.5 / 2.8 × 5 / 3 × 6 / 2.8 × 6.5 / 3.4 × 7.5 | |||||||||

| Grade | Stainless Steel Wire Chemical Composition (%) | |||

|---|---|---|---|---|

| C | Ni | Mn | Cr | |

| 304 | ≤ 0.08 | 8.0–10.5 | ≤ 2.0 | 18.0–20.0 |

| 321 | ≤ 0.08 | 9.0–12.0 | ≤ 2.0 | 17.0–19.0 |

| 316L | ≤ 0.03 | 10.0–14.0 | ≤ 2.0 | 16.0–18.0 |

QS-V

QS-Q

QS-VD

QS-S-VD

QS-S-Q

QS-S-WD

QS-S-RD

QIUSUO sieve bend screens are available in three standard arc lengths, and we can also provide customized sieve bend dimensions to meet your application requirements.

QIUSUO can assist in design based on application needs and requirements, leveraging extensive experience and expertise to produce high-quality, multi-specification sieve bend screen products with fast delivery times.

Sieve bend screens are widely used in the coal, chemical, and environmental protection industries. They are primarily employed for pre-dewatering, slurry handling, and desliming operations of moving materials in coal-fired power plants and mining facilities, as well as for classification and slurry recovery. They can also be used in combination with hydrocyclones for processing fine particle materials, enabling efficient classification, dewatering, slurry treatment, and desliming.