Product display

- 家

- 产品

- 行业

- 制造

- 服务

- 技术

- 安全光栅走道

- 安全格栅楼梯踏板

- 安全格栅梯子横档

- 安全格栅脚手架板

- 用于采矿筛分的穿孔金属振动筛

- 砖厂振动筛

- 啤酒厂土豆泥地板

- 制糖业

- 谷物工业

- 造纸工业

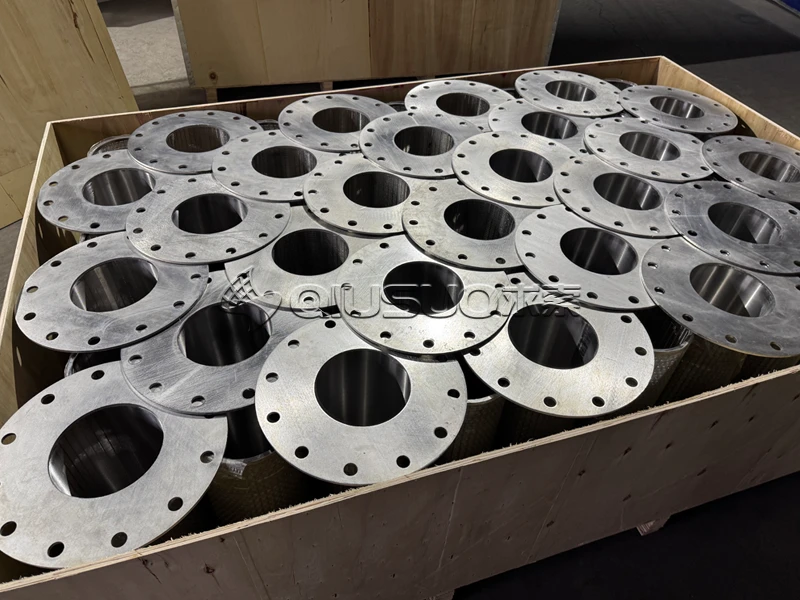

- 管道明细表

- 金属线规图

- 金属板量规图

- 数控冲床的优点有哪些?

- 钻孔筛板表面喷砂有什么好处?

- 各种进气屏的比较

- 为什么要为啤酒厂的Mash Tun假底选择楔形丝网?

- 为什么双螺杆压力机更喜欢钻板?

- DSM屏幕提高了处理效率

- PVDF涂料和粉末涂料有什么区别?

- 用于检查编织金属丝布的检查和测试设备

- 如何计算不锈钢电焊网的重量?

- 施工类型流动方向楔形丝网管

- 丝网滤芯和滤网的一般类型有哪些?

- 用于检查穿孔金属的检查和测试设备

- 编织丝网和布的材料等级是什么?

- 不锈钢焊丝网板的边缘类型有多少?

- 焊接丝网的开口和网孔有什么区别?

- 我们可以制造哪些孔图案穿孔金属防滑安全光栅?

- 楔形丝网大大提高制糖效率

- 不锈钢丝布快速简便的参考数据和订购提示

- 穿孔金属管和穿孔金属管有什么区别?

- 如何为您的金属丝网产品选择不锈钢材料等级?

- 如何选择金属丝网?

- 不锈钢丝网/丝网参考数据和订单提示

- 如何计算不锈钢丝网重量?

- 计算器

- 下载

- 询价表格

- 技术

- 案例研究

- 工业过滤线布

- 楔形丝网过滤器

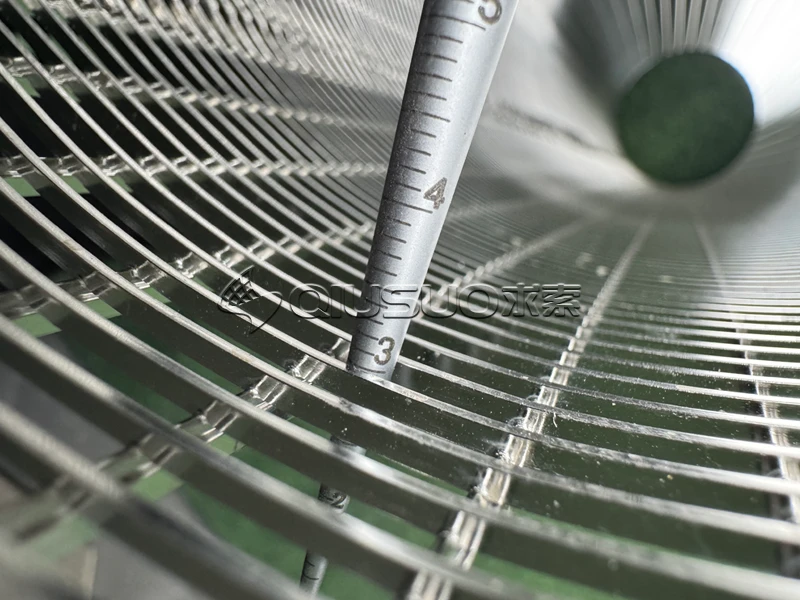

- 390 mm Flange Diameter Wedge Wire Screen Cylinder

- 0.1 & 0.3 mm Slot Wedge Wire Filter Elements

- SS304楔形丝筛筒

- SS304楔形铁丝网水分配器

- SS304楔形丝进气滤网

- SS316楔形线过滤器喷嘴

- 6英寸FNPT楔形线槽管

- BSPT螺纹楔形丝滤网滤芯

- 双面2205楔形丝网滤网

- SS304扁平楔形丝筛板

- SS316楔形线屏幕面板

- T型进气滤网

- 楔形铁丝网下分配器

- 楔形线头横向组件

- S32750楔形丝筛筒

- SS316L楔形丝筛筒

- SS304楔形丝筛筒

- SS304螺旋压力机分离器

- 圆形支撑杆楔形金属丝筛板

- 80 微米楔形丝筛管

- 滚筒式进气滤网

- 带框架的楔形丝网

- SS304筛弯管筛

- SS304楔形丝过滤网

- 双面2205楔形丝筛管

- 哈氏合金C276耐腐蚀楔形丝网管

- 1英寸 #150 BSPT楔形丝筛网过滤器侧面

- 3/4 "NPT螺纹喷嘴,高效过滤

- 具有高强度和刚度的楔形钢丝横向组件

- M45x2.0 FOTI 0.2毫米槽形楔形丝网

- 《O.D.》 54毫米楔形丝筛管

- 振动楔形丝筛板

- 污水处理 DSM 过滤器

- 美国羽绒服公司楔形丝网面板

- 120 用于淀粉筛选的50微米DSM筛网

- 螺纹接头楔形丝网容器内的水分配器

- 外径为33 mm的楔形丝网

- 带有矩形支撑杆的平板屏幕

- 楔形线进气滤网作为进气系统的防护

- 1英寸NPT楔形丝网喷嘴

- 压载水处理系统用楔形线滤筒

- 双2507小进气屏

- 20微米楔形丝网过滤器

- 过滤罐用平板双流级过滤喷嘴

- 楔形线筛网篮

- 农业分公司螺旋压力机分离器楔形丝网

- 啤酒厂楔形丝网

- 水泵工程用楔形丝网管

- 化工厂用楔形线过滤网段

- 离子交换及其他介质过滤系统用树脂捕集筛

- 水处理系统用楔形丝网侧边

- 配水系统用楔形丝网滤嘴

- 焊接加工公司用楔形丝网管

- DSM制糖筛

- 化肥厂用楔形丝网喷嘴

- 120 ° 静态淀粉DSM筛网

- 楔形线滴水盘

- 楔形丝网分配器和树脂疏水阀

- SS304楔形丝网横向

- 0.4毫米槽楔形丝网平板

- 楔形丝网洗涤器

- 楔形丝网水分配器

- 工业穿孔金属

- SS304和蒙奈尔焊接穿孔金属管

- 18.8% 开孔率穿孔金属盘式过滤器

- 316L不锈钢穿孔管

- 锥形滤筒高度86.9毫米

- SS316扇形穿孔板

- 离心机筛网用激光穿孔板

- 定制不锈钢滤篮

- Q235B低碳钢金属穿孔板

- SS304弯曲穿孔板

- 150毫米O.D. 钻孔穿孔金属盘

- 激光方形穿孔板:

- 激光打孔微穿孔圆盘

- 0.6毫米激光打孔穿孔金属圆筒

- 0.3毫米激光微穿孔板

- 0.15毫米激光切割穿孔金属环

- 0.1毫米激光微穿孔板

- 圆孔穿孔网筛

- 用于双辊压机的微孔穿孔金属

- 穿孔管式滤芯

- 带加强支撑的钻孔穿孔金属圆筒,2毫米厚度

- 不锈钢304微钻孔金属过滤筒装置

- 6毫米厚钻孔穿孔金属盘

- 0.5毫米孔径穿孔板

- 用于咖啡过滤的0.4毫米微穿孔网

- 钻孔穿孔脱水垫板

- 带孔滤盘

- 冲孔网圆筒

- Drilling Perforated Metal Plate For Iran Petrochemical Industry

- SS316 0.5毫米直径微穿孔板

- 镀锌金属网格

- 不同孔径和内径的穿孔管

- 纸浆钻孔穿孔筛板

- 冲压螺钉穿孔板

- 钻孔和铣削穿孔板

- 脱水设备制造用穿孔金属

- 开槽铝穿孔金属板

- 定制特殊图案穿孔金属板

- 带涡轮风扇孔图案的穿孔金属板

- 镀锌钢矩形孔金属板

- 定制特殊图案穿孔金属板

- 机械设备用穿孔金属管

- 方形孔镀锌钢板

- 给料机厂用穿孔镀锌钢板

- 食品工业用微孔穿孔金属板

- 微孔穿孔金属板

- 工业过滤用穿孔金属

- 光学涂层用微孔穿孔金属板

- 304L 4 '× 8' R4T6穿孔板

- 70% 开口六边形穿孔光栅

- 6毫米孔不锈钢穿孔板

- 2毫米孔不锈钢穿孔板

- TP321穿孔波纹板

- 电机用SS316L穿孔网盘

- 蚀刻微孔穿孔金属圆盘

- 钢制穿孔金属管

- 建筑穿孔金属

- 穿孔金属安全格栅

- 条形光栅

- 不锈钢焊接网

- 金属网

- 采矿筛网

- PU屏幕

- 其他金属制品

- 橡胶筛网

- 关于我们

- 联系我们