Product display

- Ev

- Ürünler

- Delikli metal ürünler

- Metal ızgara

- Kama tel ekranlar

- Kama tel yuvası tüpleri

- Kama tel süzgeç elemanları

- Düz kama tel ekran panelleri

- Eleme bükme kama tel ekranı

- Nişasta için basınç ark ekranı

- Kama tel ızgaraları

- Giriş ekranları

- Gemi yanal meclisi

- Reçine tuzak ekranı

- Filtre nozulu

- Kama tel ekran silindiri

- Vida basın ekranı

- Döner tambur ekranı

- Basınç ekran davul

- Metal tel örgü

- Pu ekran

- Sanayi

- İmalatlar

- Hizmet

- Teknoloji

- Güvenlik ızgara geçit

- Emniyet ızgarası merdiven sırtı

- Güvenli ızgara merdiveni basamak

- Emniyet ızgara iskele tahta

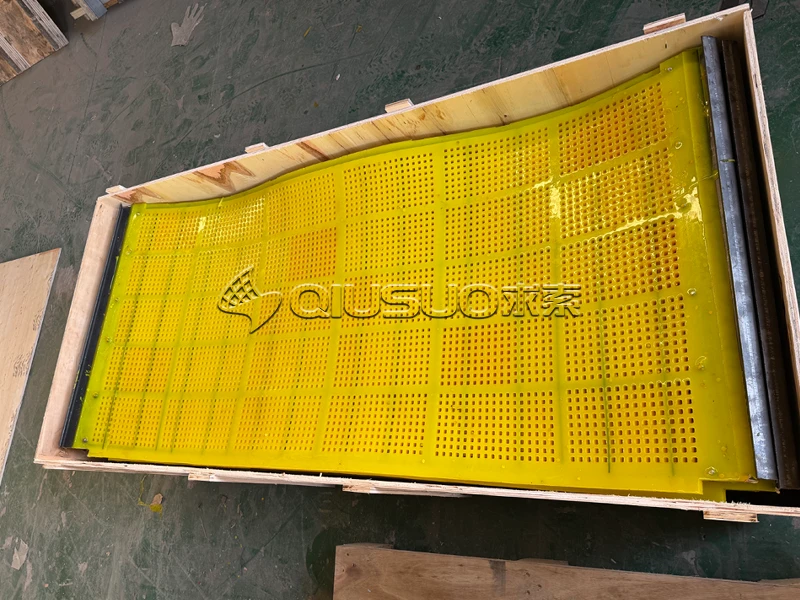

- Madencilik taraması için delikli metal titreşimli elek

- Tuğla bitki titreşimli ekran

- Bira tun tun zeminler

- Şeker endüstrisi

- Tahıl endüstrisi

- Kağıt yapım endüstrisi

- Boru çizelgesi çizelgesi

- Metal tel göstergesi tablosu

- Metal plakalar ölçü tablosu

- Cnc delme avantajları nelerdir?

- Sondaj ekran plakasının yüzey kumlama faydaları nelerdir?

- Çeşitli giriş ekranlarının adresi

- Neden brewery tun tun yanlış alt için kama tel ekran seçin?

- Neden ikiz vidalı pres makinesi sondaj plakalarını tercih ediyor?

- Dsm ekranı işleme verimverğini artırır

- PVDF Kaplama ve Toz Boya Arasındaki Fark Nedir?

- Dokuma metal tel bezi kontrol etmek için muayene ve test ekipmanları

- Paslanmaz çelik kaynaklı tel örgü ağırlığı nasıl hesaplanır?

- Inşaat türleri akan yön kama tel ekran tüpü

- Tel örgü filtre elemanları ve süzgeçlerin genel türleri nelerdir?

- Delikli metali kontrol etmek için muayene ve test ekipmanları

- Dokuma tel örgü ve kumaş için hangi malzeme sınıfı?

- Paslanmaz çelik kaynak tel örgü panellerinin kaç kenar tipi?

- Tel örgü kaynak için açılış ve örgü arasındaki fark nedir?

- Hangi delikler desen delikli metal anti-slips güvenlik ızgaraları yapabiliriz?

- Kama tel ekranı şeker üretim verimliliğini son derece artırır

- Paslanmaz çelik tel kumaş için hızlı ve kolay referans verileri ve sipariş ipuçları

- Delikli metal boru ve delikli metal borular arasındaki fark nedir?

- Metal tel örgü ürünleriniz için paslanmaz çelik malzeme sınıfı nasıl seçilir?

- Metal tel örgü nasıl seçilir?

- Paslanmaz çelik tel örgü/tel kumaş referans verileri ve sipariş ipuçları

- Paslanmaz çelik tel örgü ağırlığı nasıl hesaplanır?

- Hesap makineleri

- Indir

- Rfq formları

- Teknoloji

- Vaka çalışmaları

- Sanayi filtreleme tel bezi

- 100 Mesh paslanmaz çelik tel örgü

- Ss310 paslanmaz çelik dokuma tel kumaş

- 50 mesh paslanmaz çelik dokuma tel kumaş

- 3 mesh selvage kenar dokuma tel örgü

- 325 × 2300 mesh hollandalı örgü tel örgü kumaş filtresi

- 260 × 40 mesh

- 132 × 17 mesh

- Filtre tel bezi

- 8mesh selvage paslanmaz çelik tel örgü

- 6mesh paslanmaz çelik tel örgü

- 4 mesh× 0.8mm teller paslanmaz çelik tel örgü

- 3 × 3mesh selvage paslanmaz çelik tel örgü

- 60 mesh× 0.15mm tel kumaş kemer

- 310 40 mesh × 0.25mm tel kumaş

- Ters hollandalı tel kumaş kemer

- 4 × 4mesh selvage paslanmaz çelik tel kumaş

- 12 × 64mesh düz hollandalı örgü tel örgü

- Paslanmaz çelik tel örgü filtre diski

- Kama tel ekran filtreleri

- 390 mm Flange Diameter Wedge Wire Screen Cylinder

- 0.1 & 0.3 mm Slot Wedge Wire Filter Elements

- Ss304 kama tel ekran silindiri

- Ss304 kama tel ekran su dağıtıcısı

- Ss304 kama tel giriş ekranı

- Ss316 kama tel filtre nozulu

- 6 inç fnpt kama tel yuvası tüpleri

- Bspt iplik kama tel ekran filtre elemanları

- Dubleks 2205 kama tel ekran süzgeci

- Ss304 düz kama tel ekran panelleri

- Ss316 kama tel ekran paneli

- T tipi giriş ekranı

- Kama tel ekran alt distribütörü

- Kama tel başlık yanal meclisleri

- S32750 kama tel ekran silindiri

- Ss316l kama tel ekran silindiri

- Ss304 kama tel ekran silindirleri

- Ss304 vidalı pres ayırıcı

- Yuvarlak destek çubuğu kama tel ekran panelleri

- 80 Mikron kama tel ekran tüpü

- Davul tipi giriş ekranı

- Çerçeve ile kama tel ekran

- Ss304 elek bükme ekranı

- Ss304 kama tel filtre ekranı

- Dubleks 2205 kama tel ekran tüpü

- Korozyon direnci ile hastelloy c276 kama tel ekran tüpü

- 1 ''#150 bspt kama tel ekran filtresi yanal

- Verimli filtreli 3/4 "npt dişli nozul

- Yüksek mukavemet ve sertlik ile kama tel yanal meclisleri

- M45x2.0 foti 0.2mm yuva kama tel ekranları

- O. d. 54mm kama tel ekran tüpü

- Titreşim kama tel ekran paneli

- Kanalizasyon arıtma dsm ekranları

- Amerikan aşağı ceket şirketi için kama tel ekran paneli

- 120 Nişasta taraması için derece 50 mikron dsm ekranı

- Gemi içinde iplik eklem kama tel ekran su distribütörü

- 33mm dış çaplı kama tel ekranlar

- Dikdörtgen destek çubuklu düz ekran

- Giriş sistemi için koruma olarak kama tel giriş ekranı

- 1 inç npt kama tel ekran nozulu

- Balast su arıtma sistemleri için kama tel filtre kartuşu

- Dubleks 2507 küçük giriş ekranı

- 20 mikron kama tel ekran filtresi

- Filtrasyon tankı için düz plaka çift akış değerlendirme filtre nozulu

- Kama tel ekran sepeti

- Tarım şubesi için vidalı pres ayırıcı kama tel ekranları

- Bira fabrikası için kama tel ekran ızgarası

- Su pompası projesi için kama tel ekran tüpü

- Kimyasal tesis için kama tel filtre ekran segmentleri

- İyon değişimi ve diğer medya filtre sistemleri için reçine tuzak ekranı

- Su arıtma sistemi için kama tel ekran yanalları

- Su dağıtım sistemi için kama tel ekran filtre nozulu

- Kaynak ve işleme şirketi için kama tel ekran tüpü

- Şeker yapımı için dsm ekranı

- Gübre tesisi için kama tel ekran nozulu

- 120 ° statik nişasta dsm ekranı

- Kama tel damlama tepsisi

- Kama tel ekran distribütörleri ve reçine kapanı

- Ss304 kama tel ekran yanalları

- 0.4mm yuvaları kama tel ekran düz paneller

- Kama tel ekran yıkayıcı

- Kama tel ekran su dağıtıcısı

- Sanayi delikli metal

- Ss304 & monel kaynaklı delikli metal borular

- 18.8% Open Rate Perforated Metal Disc Filters

- 316L Stainless Steel Perforated Tube

- Height 86.9 mm Conical Filter Cartridge

- Ss316 fan şeklindeki delikli plakalar

- Santrifüj ekranı için lazer delikli plaka

- Özel paslanmaz çelik filtre sepeti

- Q235b hafif çelik metal delikli plaka

- Ss304 bükme delikli plaka

- 150mm o. d. Delikli metal disk delme

- Lazer kare delikli plaka

- Lazer delme mikro delikli disk

- 0.6mm lazer delme delikli metal silindir

- 0.3mm lazer mikro perforasyon plakası

- 0.15mm lazer kesim delikli metal halka

- 0.1mm lazer mikro perforasyon plakası

- Yuvarlak delikli delikli mesh ekran

- Ikiz rulo basın için mikro delik delikli metal

- Delikli boru filtre elemanı

- Güçlendirilmiş destek, 2mm kalınlığında delikli metal silindir delme

- Paslanmaz çelik 304 mikro delinmiş metal filtre silindir cihazı

- 6mm kalınlığında delme delikli metal disk

- 0.5mm delik çapı delikli plaka

- Kahve filtreleme için 0.4mm mikro delikli örgü

- Delikli susuzlaştırma destek plakası delme

- Delikli filtre diski

- Delikli metal örgü silindir

- İran petrokimya endüstrisi için delikli metal levha delme

- Ss316 0.5mm çaplı mikro delikli plaka

- Galvanizli metal ızgara

- Farklı delik boyutları ve iç çapları ile delikli tüpler

- Kağıt hamuru sondaj delikli ekran plakaları

- Basın vida delikli plaka

- Delinmiş ve öğütülmüş delikli plakalar

- Susuzlaştırma ekipmanı üretimi için delikli metal

- Oluklu alüminyum delikli sac

- Özel desenli özelleştirilmiş delikli sac

- Turbofan delik desenli delikli sac

- Galvanizli çelik dikdörtgen delikli sac

- Özel desenli özelleştirilmiş delikli sac

- Makine ve ekipman için delikli metal boru

- Kare delikli galvanizli çelik sac

- Besleme makinesi fabrikası için delikli galvanizli çelik sac

- Gıda endüstrisi için mikro delikli delikli metal levha

- Mikro delikli delikli metal plaka

- Endüstriyel filtreleme için delikli metal

- Optik kaplamalar için mikro delikli delikli metal plaka

- 304l 4 '× 8 'r4t6 delikli sac

- % 70 açılış altıgen delikli ıztings

- 6mm delik paslanmaz çelik delikli plakalar

- 2mm delik paslanmaz çelik delikli sac

- Tp321 delikli oluklu plakalar

- Elektrik motorları için ss316l delikli örgü diskleri

- Kazınmış mikro delik delikli metal diskler

- Çelik delikli metal boru

- Mimari delikli metal

- Özel ss316l oluklu delikli metal paneller dekoratif ve mimari

- Bina duvar kaplaması için galvanizli dekoratif özel delik şekli delikli sac

- 6061 6061 T6 dekoratif alüminyum delikli paneller

- Inşaat projesi için delikli oluklu levha

- Dış duvar dekorasionu için delikli alüminyum levha

- Dış duvar dekorasyonu için oluklu delikli alüminyum levha

- Otomatik 4s dükkanı için dış duvar alüminyum levha

- Oluklu delikli sac kaplama

- Özelleştirilmiş güneş kalkanı panelleri

- Delikli alüminyum oluk kapakları

- Üçgen delikli delikli levhalar

- Delikli ayna paslanmaz çelik panel

- Üçgen delikli alüminyum delikli paneller

- Alüminyum delikli sac

- Delikli oluklu metal paneller

- Delikli metal emniyet ızgarası

- Eşkenar dörtgen kilit ve yuvarlak kaldırma emniyet ızgarası

- A5052-H32 kavrama dikme tahta emniyet ızgarası

- Ss304 kavrama dikme tahta emniyet ızgarası

- Koparma yıldız emniyet ızgarası

- Ss316 çekiş sırt tahta ızgara kaymaz ve pas direnci

- Önleyici skid çukur galvanizli metal örgü

- Adım PRF-5-GRIP çekiş sırt tahta ızgara

- Açık endüstriyel üretim için kavrama dikme tahta ızgara

- Kaymaz gamze delikli metal plakalar

- Elmas tahta güvenlik ızgarası

- Kaymaya dayanıklı merdiven pistleri

- 36 "ve 30" ağır kavrama dikme geçit

- Özelleştirilmiş koparma yıldız emniyet ızgarası

- 10 "5 delikli perf-o kavrama emniyet ızgarası

- Sıcak daldırma galvanizli elmas kavrama tahta

- Perf-o kavrama geçit ızgarası

- Kilit emniyet ızgara tahta

- Gemiler merdivenleri için çekiş kavrama plakaları

- Bar ızgara

- Paslanmaz çelik kaynak örgü

- 3 mm Wire Diameter Stainless Steel Wire Mesh

- Astm 304l paslanmaz çelik kaynaklı hasır

- Astm 316l paslanmaz çelik kaynaklı hasır

- Titanyum kaynaklı tel örgü

- Sus ss316l paslanmaz çelik kaynak örgü

- Astm ss316l paslanmaz çelik kaynaklı mesh

- Dikdörtgen açılış paslanmaz çelik kaynaklı örgü

- Astm ss316l 1/2 inç basınçlı kaynaklı ekran

- Astm ss321 kaynaklı hasır

- 1 inç x 1.5mm paslanmaz çelik kaynaklı örgü

- Astm ss316 1/4 "kaynak hasır

- Genişletilmiş metal örgü

- Madencilik ekran örgü

- 80 mm Opening Crimped Wire Mesh

- Aisi 321 kıvrımlı tel örgü

- 10mm tel çapı kendi kendini temizleyen ekran örgü

- 4.5 mm Wire Diameter 65Mn Metallic Screens

- 1.5 & 1.6 mm Wire Diameter Woven Wire Slotted Mesh

- 65mn yüksek karbon sıkma tel örgü

- 65mn kıvrımlı tel örgü

- 65mn oluklu metal örgü

- 65mn kare örgü metal ekran

- Mineral ekran yapmak için 65mn çelik tel

- Ince işlenmiş 65mn kıvrımlı örgü ekran

- Düz kancalı 65mn kıvrımlı tel örgü

- Madencilik için 65mn kıvrımlı tel örgü

- Takviyeli kefen bantlı kenarlı kıvrımlı tel örgü

- Daha küçük mineralleri eleme için kama tel ekran paneli

- Ss321 kıvrımlı tel örgü

- Toz boya 65mn tarama

- Tuğla fabrikası için 65mn kıvrımlı tel örgü

- Pu ekranlar

- Diğer metal ürünler

- Kauçuk ekran örgü

- Sanayi filtreleme tel bezi

- Hakkımızda

- Bize ulaşın