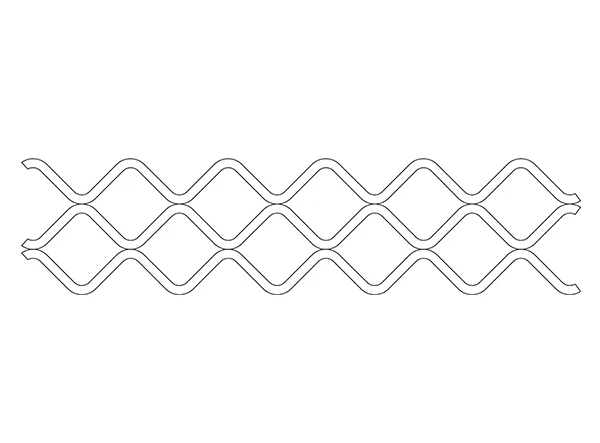

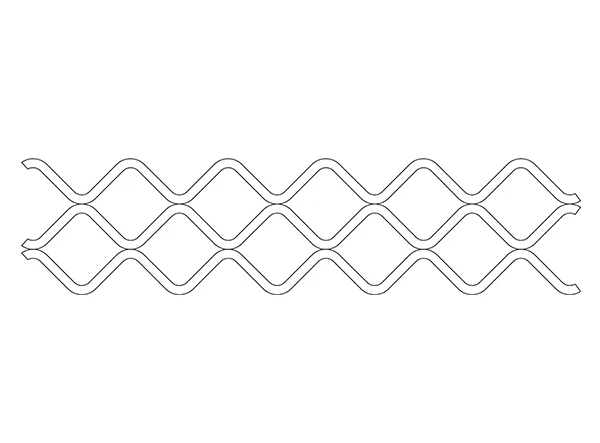

D网格

钻石开口| 等级 | 高碳钢丝化学成分(%) | 等级 | 不锈钢丝化学成分 (%) | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | 锰 | C | Ni | 锰 | Cr | ||

| 45 | 0.42-0.50 | 0.52-0.60 | 0.50-0.80 | 304 | ≤ 0.08 | 8.0-10.5 | ≤ 2.0 | 18.0-20.0 |

| 50 | 0.47-0.55 | 321 | ≤ 0.08 | 9.0-12.0 | ≤ 2.0 | 17.0-19.0 | ||

| 55 | 0.52-0.60 | 316 | ≤ 0.08 | 10.0-14.0 | ≤ 2.0 | 16.0-18.0 | ||

| 60 | 0.57-0.65 | 2205 | ≤ 0.03 | 4.5-6.5 | ≤ 2.0 | 21.0-23.0 | ||

| 65 | 0.62-0.70 | 2207 | ≤ 0.03 | 6-8 | ≤ 1.2 | 24.0-26.0 | ||

| 70 | 0.67-0.75 | - | - | - | - | - | ||

| 65Mn | 0.62-0.70 | 0.90-1.20 | - | - | - | - | - | |

| 72A | 0.70-0.75 | 0.15-0.75 | 0.30-0.60 | - | - | - | - | - |

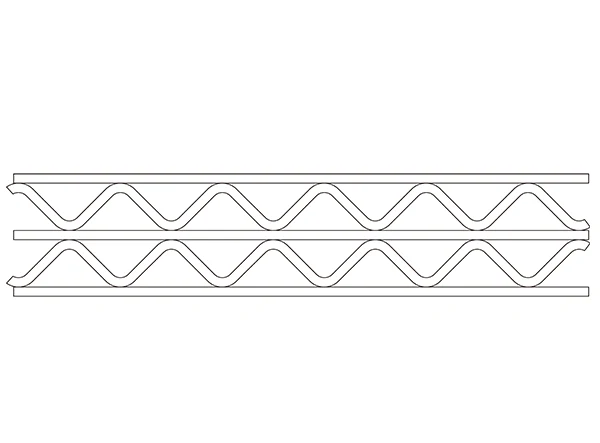

QIUSUO可以根据应用需求和要求协助设计,利用丰富的经验和专业知识,以快速的交货时间生产高质量,多规格的聚氨酯防堵塞筛板产品。

适用于筛选高水分含量和高粘度的材料。 推荐用于具有明确定义的颗粒形状的材料。